-264-

ENGINE MANAGEMENT SYSTEM

- 264 -

COMPONENTS OF EMS

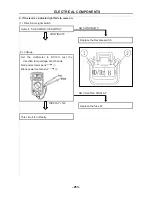

Electronic Control Unit

1

.

Description & Working Principle

The ECU continuously monitors the operating conditions of the engine through the system

sensors. It also provides the necessary computation, adaptability, and output control in order to

minimize the tailpipe emissions and fuel consumption, while optimizing vehicle drivability for all

operating conditions. The ECU also provides diagnosis when system malfunctions occur.

2

.

Handling – DOs & DONTs

ECU Handing

ACTION REASON

DO NOT

:

Place the ECU close to the exhaust

pipe or Engine when removed

High temperature might reduce the life of the

ECU and also can damage the ECU

DO NOT

:

Place the ECU close to or pour

water, oil or any other liquids.

ECU is susceptible to water and liquids

DO NOT

:

Allow mud or other debris to

accumulate on the surface of the ECU

Having mud or debris accumulated on the

ECU casing reduces its heat dissipation

efficiency.

DO NOT

:

Apply any voltage relative to any

point to the ECU

Drastically affects the performance of the

ECU and may lead to ECU damage

DO NOT

:

Clean ECU with any solvent or any

corrosive liquid

Can damage the housing of the ECU

DO:

Take

extreme care that water droplets or

excess moisture should not fall on ECU

connectors

ECU connectors can get short and may

lead to ECU damage

DO:

Clean the ECU with a moist cloth and

keep it dry

Prevents ECU damage

3

.

Installation requirements

The ECU shall be mounted using M5 machined screws with a torque of 3.9Nm ± 10%. The

mounting surface should also be flat to avoid subjecting the base plate to unnecessary force and

warping the PCB.

4

.

Maintenance service and Repair

ECU is a non-serviceable part. Once there are problems, it’s important to first determine if the

problem is caused by software/calibration. If it is caused by software/calibration, please refer to

software/calibration reflashing procedure. In the event of ECU hardware failure or malfunction

(during warranty period only) the ECU should be sent back to the vehicle manufacturer giving

complete details of the ECU Part No, Serial number, Vehicle Model & Make, manufacturing Date,

Total kms run on the vehicle, Location of use, Vehicle No, Date of return.

ENGINE MANAGEMENT SYSTEM

- 265 -

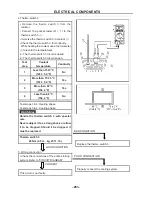

Multec 3.5 Injectors

1

.

Description and Working Principle

The Multec 3.5 Fuel Injector is an electromechanical device. A magnetic field is generated as

voltage is applied to the solenoid coil.

The resulting magnetic force lifts the core assembly, overcoming manifold vacuum, spring force,

and fuel pressure, allowing fuel to pass through the ball and seat interface to the director.

As the fuel passes through the director, an atomized spray is developed. The injector closes

when the voltage is removed, cutting off the fuel flow.

2

.

Handling - DOs & DONTs

3.5 FUEL INJECTOR HANDLING

ACTION REASON

DO NOT

:

Re-use injector seal rings if at all

possible. If no other choice exists, take

extra care in inspecting the seal rings for

damage.

Leakage.

DO NOT

:

Dip injector tips into lubricants.

Can plug injector spray orifices.

DO NOT

:

Cycle injector repeatedly without

fuel pressure.

Damage to internal mechanical components.

DO NOT

:

Pulse (actuate) a suspected high

leak rate injector (leak >50 sccm air).

Can dislodge internal contamination if

present and preclude root cause analysis.

DO NOT

:

Allow water to enter fuel system

from air lines, etc. during leak checks.

Can damage injectors.

DO NOT

:

Contact or apply load to the

injector tip for installation.

Apply load to 45 deg angle on nylon over

mold see

DO NOT

:

Pound injectors into manifold

during assembly to engine.

Can damage injectors or seal rings.

DO NOT

:

Apply excessive side loads to

electrical connectors.

May cause loss of electrical continuity.

DO NOT

: Use any dropped unit.

Internal damage may have occurred.

DONOT

:

Store injectors, rails, or

subassemblies including engines on which

the injectors have been installed in an

unprotected environment.

External contamination can damage the

injector electrically and/or mechanically.

DO NOT

:

Use the injector as a handle.

Do not use the injector to lift assemblies

DO NOT

:

Rack, stage, or handle parts in a

manner that allows contact between parts.

Damage will occur.

DO NOT

:

Remove packing in a way that

allows contact between parts.

Damage could occur due ton contact

between parts.

Содержание HS200UTV

Страница 3: ......

Страница 15: ......

Страница 94: ... 79 SPECIFICATIONS 79 HYDROGRAPHIC CHART Hydrographic chart Pressure ...

Страница 95: ... 80 SPECIFICATIONS 80 LUBRICATION OIL WAY LUBRICATION OIL WAY Pressure splashing oil ...

Страница 248: ... 233 CHASSIS 233 Fuel tank cap Remove the fuel tank cap by turning it counterclockwise ...

Страница 263: ... 248 ...

Страница 304: ... 289 ...

Страница 305: ... 290 ...

Страница 306: ... 291 ...

Страница 307: ... 292 ...

Страница 308: ... 293 ...

Страница 309: ... 294 ...

Страница 310: ... 295 ...

Страница 311: ... 296 ...

Страница 312: ...TM HISUN MOTORS 310 East University Dr McKinney Texas 75069 PH 972 446 0760 TF 877 838 6188 hisunmotors com ...