May 2017

PLT-02496, Version: 1.2

Page 5-11

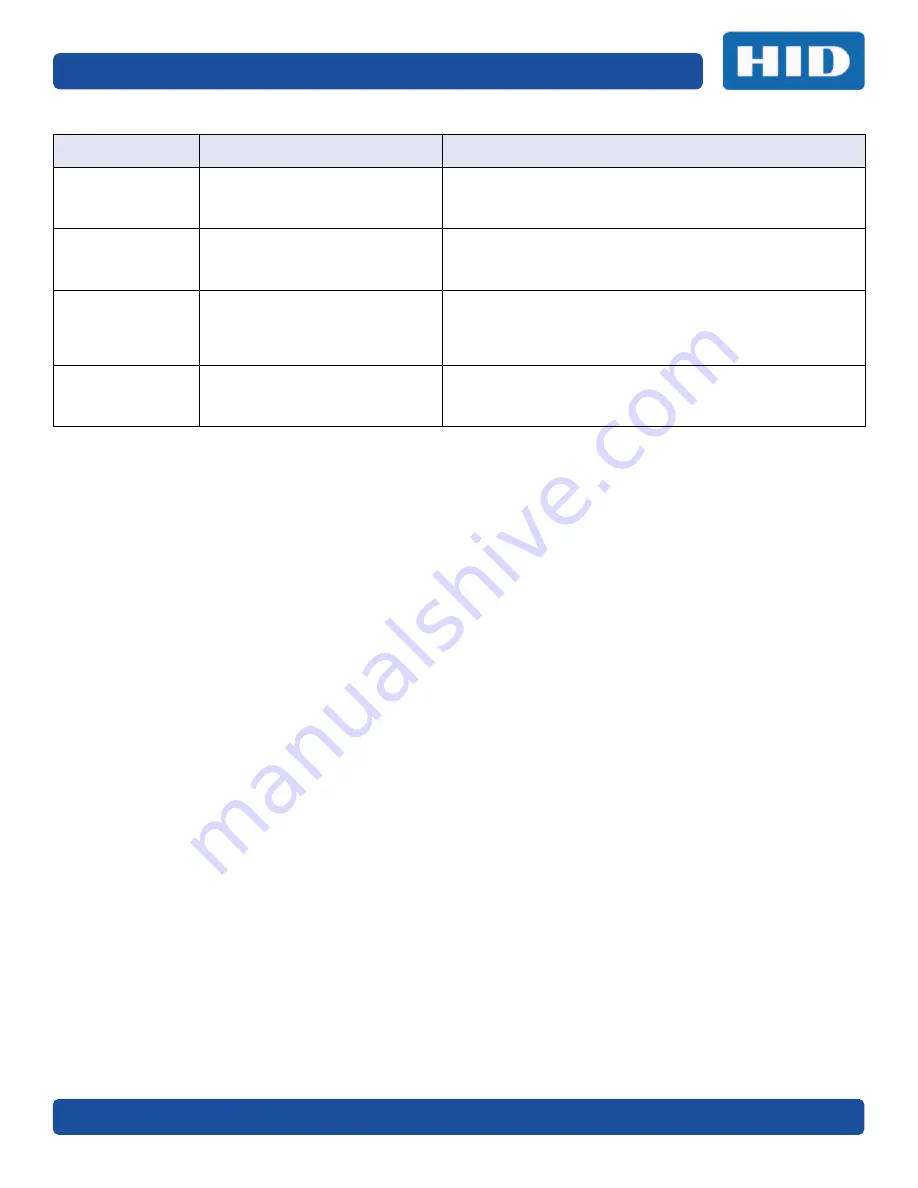

Troubleshooting

#367

Laminator

Calibration Error

The Laminator is unable to

calibrate the LAM1 card position

sensor.

Clear any cards in the Laminator. Press the Resume button to

continue. If the error persists, contact Technical Support.

#368

Laminator

Calibration Error

The Laminator is unable to

calibrate the LAM2 card position

sensor.

Clear any cards in the Laminator. Press the Resume button to

continue. If the error persists, contact Technical Support.

#369

Laminator

Calibration Error

The Laminator is unable to

calibrate the output hopper

sensor.

Clear any cards in the Laminator and Laminator output

hopper. Close the Laminator output hopper door. Press the

Resume button to continue. If the error persists, contact

Technical Support.

#370

Laminator

Calibration Error

The Laminator is unable to

calibrate.

Clear any cards in the Laminator. Press the Resume button to

continue. If the error persists, contact Technical Support.

Error Message

Cause

Solution

Содержание FARGO DTC 5500LMX

Страница 1: ...hidglobal com FARGO DTC 5500LMX CARD PRINTER MODEL X002100 USER GUIDE PLT 02496 Version 1 2 May 2017...

Страница 9: ...May 2017 PLT 02496 Version 1 2 Specifications Page 1 5 1 2 3 Safety Messages Taiwan...

Страница 10: ...Page 1 6 Specifications PLT 02496 Version 1 2 May 2017 1 2 4 Safety Messages China 6 2000m 5R 6...

Страница 54: ...ToolBox Page 4 10 PLT 02496 Version 1 2 May 2017 This page intentionally left blank...

Страница 68: ...Troubleshooting Page 5 14 PLT 02496 Version 1 2 May 2017 This page intentionally left blank...

Страница 70: ...Firmware Upgrades Page 6 2 PLT 02496 Version 1 2 May 2017 This page intentionally left blank...

Страница 72: ...Technical Support Page 7 2 PLT 02496 Version 1 2 May 2017 This page intentionally left blank...

Страница 74: ...hidglobal com...