22

for the technician

First firing, regulation and servicing instructions

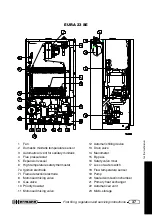

— To make gas pressure controls, insert manometer probes in pressure tapping points available

on to gas valve (see picture).

Note: To check that gas pressure and flowrate are sufficient to guarantee perfect boiler operations,

make such controls while burner is working.

MAX-MIN pressure adjustment

on GAS valve

— Unscrew (2-3 rounds) the screw in outlet pressure tap-

ping point [1] on gas valve and plug in manometer

probe. On “SE” models, unplug silicon rubber pipe (com-

ing from sealed chamber) from “Vent” plug [3];

— start the boiler at maximum power (not modulating)

proceeding

preferably

as described in “Combustion

check” paragraph; as alternative, proceed as follows:

•

set the domestic hot water temperature to the

maximum value;

•

open an hot water tap fully (flow rate 10 l/minute,

open more than one tap if needed), wait for the

stabilization of the pressure (at least 20 seconds);

— verify that pressure correspond to the MAX value indi-

cated in the table “BURNER POWER / PRESSURES”

(see following pages);

— unplug one of modulation coil supply connectors [4]

and check that pressure correspond to the MIN value

indicated in the table “BURNER POWER / PRES-

SURES”, then plug the connector back in;

— if it is necessary to adjust settings, proceed as follows,

according to the figure:

•

remove protection cap [C];

•

adjust MAX pressure by turning bigger nut [B] (8 mm). Clockwise to increase pressure,

counterclockwise to decrease;

•

unplug again one of connectors [4];

•

adjust MIN pressure by turning smaller nut [A] (5 mm) while keeping bigger nut [B] stopped.

Clockwise to increase pressure, counterclockwise to decrease;

•

insert connector [4] again and check that MAX pressure is not changed;

•

Fit cap [C];

Important: lock the adjustment device after any setting operation.

GAS VALVE

Pressure tapping pionts:

1 = Gas OUT

2 = Gas IN

3 = “Vent” plug (SE models)

872_R00

1

B

A

C

2

4

3