11

for the technician

Installation instructions

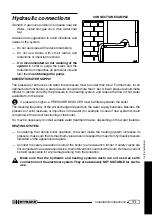

Hydraulic connections

Remark: If gas cock position is foreseen near the

WALL, install first gas cock, then water inlet

tap.

Advices and suggestions to avoid vibrations and

noises in the system

— Do not use pipes with reduced diameters;

— Do not use bends with small radius and

reductions of important sections;

—

It is recommended an hot washing of the

system

in order to purge the pipes and the

radiators from impurities (in particular oils and

fats) that

could damage the pump.

DOMESTIC WATER SUPPLY

The pressure of entrance cold water inlet pressure must be lower than 6 bar. Furthermore, for an

optimal boiler functioning, water pressure should be more than 1 bar. A lower pressure could make

difficult to restore correctly the pressure in the heating system, and reduce the flow od hot water

available from the boiler.

If pressure is higher, a PRESSURE REDUCER must be fitted upstream the boiler.

The cleaning frequency of the coil exchanger depends on the water supply hardness. Besides, the

presence of solid residuals or impurities in the water (for example in case of new systems) could

compromise the correct functioning of the boiler.

So, may be necessary to install suitable water treatment device, depending on the water features.

HEATING SYSTEM

— Considering that during boiler operation, the water inside the heating system increases its

pressure, make sure that its maximum value does not exceed the maximum hydraulic pressure

indicated on the appliance data plate.

— Connect the safety evacuation ducts of the boiler to an evacuation funnel. If safety valves are

not connected to an evacuation device, their intervention could flood the room. Hermann cannot

be held responsible for any damage arising from that situation.

Make sure that the hydraulic and heating systems ducts are not used as earth

connections of the electrical system. They are absolutely NOT SUITABLE for such a

use.

CONNECTION EXAMPLE