16

July 2003

HIGH LIMIT

This high temperature control senses the temperature of the

shortening; if the temperature of the shortening exceeds 450°F

(230°C), this control will open and shut off the heat to the frypot;

when the temperature of the shortening drops to a safe operation

limit, the control must be manually reset by pressing the red reset

button, located under the control panel, in the front of the fryer

FLAME SENSORS

Sense the pilot lights when the power switch is turned on; if the

pilots go out, or do not light, the flame sensors shut the gas off,

via the modules

GAS CONTROL VALVE

A dual controller, in which, one side of the valve controls the

pilot light and the other side controls the main burner.

AIRFLOW SWITCH

Senses the flow of air coming from the blower; if the airflow is

reduced below a set amount, the switch cuts power to the gas

control valve, which shuts down the burners

BLOWER

Adds the proper amount of air into the burner tubes, so an

efficient combustion takes place, and also, pulls the flue gases

out to the flue

AIR VALVE

Pumps air into the shortening, periodically, to keep the

shortening at a uniform temperature; this only functions when

the unit has been sitting idle for a period of time, and when

heating up from a cold start

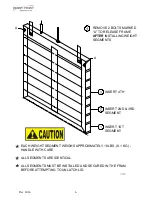

FILTER DRAIN PAN

The removable pan that houses the filter and catches the

shortening when it is drained from the frypot; also used to

remove and discard old shortening

FILTER UNION

Connects the filter to the filter pump, and allows easy removal of

the filter and drain pan

Figure 3-1

When hot shortening is in this pan, use extreme

care to avoid burns.

3-1.

OPERATING

COMPONENT

(CONT.)

Содержание OFE-391

Страница 2: ......

Страница 26: ...19 April 2003 14 1 2 3 4 5 6 7 8 9 13 11 12 10 COOK OFF PUMP ...