INSTALLATION INSTRUCTIONS

Fan Coils: FEM4X, FEM4P, REM4X, FXM4X

496 01 5503 02

9

Specifications are subject to change without notice.

Figure 10

Wiring Layout

−

Air Conditioning

Unit (Cooling and 1

−

Stage Heat)

R

G

W

Y

THERMOSTAT

R

G

W

2

W

3

E

C

FAN COIL

(CONTROL)

C

Y

AIR COND.

RED

GRY

WHT

WHT

BLU

VIO

BRN

Figure 11

Wiring Layout

−

Heat Pump Unit

(Cooling and 2

−

Stage Heat with No

Outdoor Thermostat)

R

G

C

E

L

O

Y

THERMOSTAT

R

R

C

O

Y

G

C

W

2

W

2

W

2

W

3

E

FAN COIL

(CONTROL)

HEAT PUMP

(CONTROL)

RED

GRY

BRN

WHT

BLU

VIO

Figure 12

Wiring Layout

−

Heat Pump Unit

(Cooling and 2

−

Stage Heat for

Manufactured Housing)

R

E

W

2

R

C

THERMOSTAT

FAN COIL

(CONTROL)

HEAT PUMP

(CONTROL)

G

C

W

2

E

L

G

C

R

O

Y

ODTS

O

Y

W

3

W

2

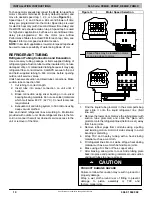

Transformer Information

Transformer is factory wired for 230V operation. For 208V

applications, disconnect the black wire from the 230V terminal

on transformer and connect it to the 208V terminal (refer to

Figure 13

Transformer Connections

230

C

208

SECONDARY

PRIMARY

BLACK

YELLOW

RED

BROWN

C. GROUND CONNECTIONS

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to establish uninterrupted or unbroken ground

could result in personal injury and/or death.

According to NEC, ANSI/NFPA 70, and local codes, the

cabinet must have an uninterrupted or unbroken ground

in order to minimize potential for personal injury or death

if an electrical fault should occur. The ground may consist

of electrical wire or metal conduit when installed in

accordance with existing electrical codes. If conduit

connection uses reducing washers, a separate ground

wire must be used.

NOTE:

Use UL listed conduit and conduit connectors for

connecting supply wire(s) to unit to obtain proper grounding.

Grounding may also be accomplished by using grounding lugs

provided in control box.

D. MINIMUM CFM AND MOTOR SPEED SELECTION

Units with or without electric heaters require a minimum CFM.

Refer to the unit wiring label to ensure that the fan speed

selected is not lower than the minimum fan speed indicated.

Fan speed selection is done at the fan motor. To change motor

speeds, reposition wire at fan motor speed terminals labeled

1

−

2

−

3 (see

.

Units with or without electric heaters

require a minimum CFM. Refer to the unit wiring label to ensure

that the fan speed selected is not lower than the minimum fan

speed indicated.

SPEED TAP SELECTION AT MOTOR CONNECTOR

Tap 1

Low

90 sec off delay

Tap 2

Medium

90 sec off delay

Tap 3

High

90 sec off delay

Tap 4

Electric Heat †

0 sec off delay

Tap 5

Max ‡

0 sec off delay

† Electric heat airflow is same CFM as Tap 3, but with 0

sec off delay.

‡ For high static applications, see Airflow Performance

Tables for max airflow.