INSTALLATION INSTRUCTIONS

Fan Coils: FEM4X, FEM4P, REM4X, FXM4X

496 01 5503 02

11

Specifications are subject to change without notice.

REFRIGERANT FLOW

−

CONTROL DE-

VICE

FEM4P Models:

These units come equipped with a

factory installed Piston

metering device with Teflon ring

. If a piston replacement is

required, check piston size shown on indoor unit rating plate

to see if it matches required outdoor piston size. The outdoor

piston size will be found on the outdoor unit rating plate,

product data or installation instructions depending on the

model shown on outdoor unit rating plate. If the fan coil piston

does not match, replace indoor piston with correct outdoor

piston. With some outdoor units a piston is shipped with

outdoor unit.

When changing piston, use a back

−

up wrench. Hand tighten

hex nut, then tighten with wrench 1/2 turn. Do not exceed 30

ft

−

lbs.

NOTE:

The indoor piston contains a Teflon ring (or seal)

which is used to seat against the inside of distributor body,

and must be installed properly to ensure proper seating in the

direction for cooling operation.

Always use outdoor units designed to match indoor fan coil

applications.

REFRIGERANT METERING DEVICE

FEM4X, REM4X, FXM4X Models:

These Fan Coils have a factory installed hard shut

−

off TXV

designed only for use with R

−

410A refrigerant. Use only with

outdoor units designed for R

−

410A.

TXV is factory set and not field adjustable.

!

CAUTION

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

This Fan Coil has a hard shut

−

off TXV metering device. A

compressor Hard Start Kit is REQUIRED in all

applications where the matching outdoor unit has a

single

−

phase reciprocating compressor.

!

CAUTION

PRODUCT OPERATION HAZARD

Failure to follow this caution may result in improper prod-

uct operation.

If using a TXV in conjunction with a single

−

phase recipro-

cating compressor, a compressor start capacitor and relay

are required. Consult outdoor unit pre

−

sale literature for

start assist kit part number.

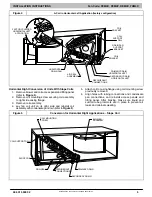

Figure 15

Refrigerant Flow

−

Control Device

TEFLON SEAL

BRASS

HEX NUT

STRAINER

PISTON

RETAINER

BRASS

HEX BODY

DISTRIBUTOR

PISTON

FLOW IN

COOLING

TEFLON RING

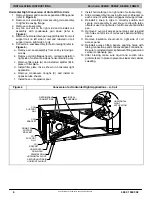

CONDENSATE DRAINS

Unit is provided with primary and secondary 3/4

” (19mm)

NPT drain connections. Refer to

,

to identify the primary and

secondary locations. To prevent property damage and

achieve optimum drainage performance, BOTH primary and

secondary drain lines should be installed and include

properly sized condensate traps (refer to

).

Factory approved condensate traps are available (accessory

part number EBAC01CTK).

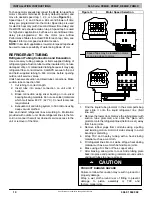

To connect drainlines, the drain connection knock

−

outs must

be removed. Use a knife to start the opening near the tab and

using pliers, pull the tab to remove the knock

−

out. Clean the

edge of the opening if necessary. After drain fittings are

installed, caulk the seam between the fitting and the cover to

retain the low leak rating of the unit.

It is recommended the PVC fittings be used on the plastic

condensate pan. Do not over

−

tighten. Finger

−

tighten plus

1

−

1/2 turns. Use pipe dope to ensure proper seal.

Install traps in the condensate lines as close to the coil as

possible (refer to

), but avoid blocking filter access

panel.

Install drain lines below the bottom of the drain pan and pitch

the drain lines down from the coil at least 1/4 inch per foot of

run (6mm per 0.3m). Horizontal runs over 15 feet (5m) long

must also have an anti

−

siphon air vents (stand pipes),

installed ahead of the horizontal runs. Extremely long

horizontal runs may require oversized drain lines to eliminate

air trapping.

Route primary drain line to the outside or to a floor drain.

Check local codes before connecting to a waste (sewer) line.

Route the secondary drain line to a place in compliance with

local installation codes where it will be noticed when unit is

operational. Condensate flowing from secondary (overflow)

drain indicates a plugged primary drain

−

unit requires

service or water damage will occur.