FIELD WIRING / GAS CONNECTION

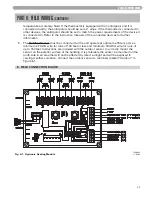

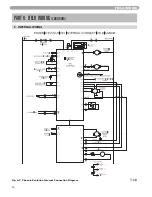

PART 6: FIELD WIRING

(CONTINUED)

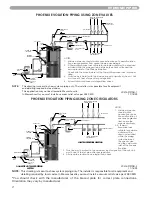

PART 7: GAS CONNECTION

A. GAS SUPPLY

The gas supply shall have a maximum inlet

pressure of less than 14" water column (350

mm), ½ pound pressure (3.5 kPa), and a mini-

mum of 3.5" water column. The entire piping

system, gas meter and regulator must be sized

properly to prevent pressure drop greater than

0.5" WC as stated in the National Fuel Gas Code.

This information is listed on the rating plate. It is

very important that you are connected to the

type of gas as noted on the rating plate. "LP" for

liquefied petroleum, propane gas or, "Nat" natu-

ral or city gas. All gas connections must be

approved by the local gas supplier, or utility in

addition to the governing authority, prior to

turning the gas supply on.

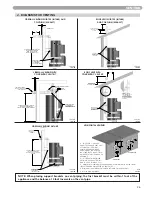

Do not remove the

reducing coupling attached to gas valve! It is

mandatory that this fitting is used for connec-

tion to a field fabricated drip leg as shown in

the illustration at right per the National Fuel

Gas Code.

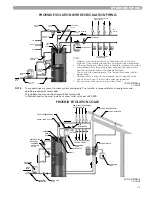

You must ensure that the entire gas line to the connection at the Phoenix Evolution is no

smaller than ¾". Once all the inspections have been performed, the piping must be leak tested. If the

leak test requirement is a higher test pressure than the maximum gas inlet pressure, you must iso-

late the Phoenix Evolution from the gas line to continue leak testing. In order to do this, you must

turn off the factory and field-installed gas cocks. This will minimize the possibility of damaging the

Phoenix Evolution gas valve.

n

WARNING

It is of extreme importance that this unit be properly grounded. It is very important that the

building system ground is inspected by a qualified electrician, prior to making this connection.

It is very important that the electrical power is only turned on when the Phoenix Evolution is

completely filled with cold water.

n

WARNING

Failure to follow all precautions in this section could result in fire, explosion or death!

UNION

DRIP LEG

Fig. 7-1

n

WARNING

Failure to isolate gas line while leak testing may damage the gas valve. In the event

the gas valve is exposed to a pressure greater than ½ PSI, 14" water column, the gas

valve must be replaced. Never use an open flame (match, lighter, etc.) to check gas

connections.

26

Содержание Phoenix Evolution

Страница 71: ...70 ...

Страница 72: ...71 ...

Страница 73: ...72 MAINTENANCE NOTES ...

Страница 74: ...73 MAINTENANCE NOTES ...

Страница 75: ...74 MAINTENANCE NOTES ...

Страница 76: ... 2009 Heat Transfer Products Inc www htproducts com LP 314 REV 12 21 09 ...