OPERATOR SAFETY

4

1739579

OWNER’S INFORMATION

Know your product:

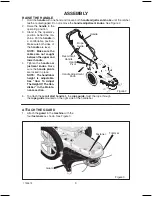

If you understand the

unit and how the unit operates, you will get

the best performance. As you read this manu-

al, compare the illustrations to the unit. Learn

the location and the function of the controls.

It is important that you read and understand

these original instructions thoroughly before

attempting to start or operate this equipment.

WARNING: Look for this symbol to indi-

cate important safety precautions. This

symbol indicates: “Attention! Become

Alert! Your Safety Is At Risk.”

Responsibility Of The Owner

WARNING: This cutting machine

is capable of throwing objects.

Failure to observe the following

safety instructions could result in serious

injury to the operator or bystanders.

The responsibility of the owner is

to follow the instructions below.

SAFETY PRECAUTIONS

I.

General Operation

1.

Read, understand, and follow all instruc-

tions on the machine and in the manu-

al(s). Be thoroughly familiar with the

controls and the proper use of the ma-

chine before starting.

2.

Familiarize yourself with all of the safety

and operating decals on this equipment

and on any of its attachments or acces-

sories.

3.

Do not put hands or feet near or under

rotating parts.

4.

Only allow responsible individuals, who

are familiar with the instructions, to oper-

ate the machine.

5.

Thoroughly inspect the area where the

machine is to be used and remove all

foreign objects. Your equipment can

propel small objects at high speed caus-

ing personal injury or property damage.

Stay away from breakable objects, such

as house windows, automobiles, green-

houses, etc.

6.

Keep the area of operation clear of all

persons, particularly small children, and

pets.

7.

Wear appropriate clothing such as a

long−sleeved shirt or jacket. Also wear

long trousers. Do not wear shorts.

8.

Do not wear loose clothing or jewelry.

They can be caught in moving parts.

9.

Always wear safety goggles or safety

glasses with side shields when operating

the machine to protect your eyes from

foreign objects which can be thrown

from the unit.

10. Always wear work gloves and sturdy

footwear. Wear footwear that will im-

prove footing on slippery surfaces. Do

not operate product when barefoot or

wearing open sandals. Leather work

shoes or short boots work well for most

people. These will protect the operator’s

ankles and shins from small sticks, splin-

ters, and other debris.

11. It is advisable to wear protective head-

gear to prevent the possibility of being

struck by small flying particles, or being

struck by low hanging branches, twigs,

or other objects which may be unnoticed

by the operator.

12. Do not operate the machine without

proper guards or other safety protective

devices in place.

13. Use this equipment for its intended pur-

pose only.

14. See manufacturer’s instructions for prop-

er operation and installation of accesso-

ries. Only use accessories approved by

the manufacturer.

15. Operate only in daylight or good artificial

light.

16. Do not operate product when fatigued or

under the influence of alcohol, drugs or

other medication which can cause

drowsiness or affect your ability to oper-

ate this machine safely.

17. Never operate machine in wet grass. Al-

ways be sure of your footing; keep a firm

hold on the handle and walk; never run.

18. Before each use, inspect the throttle

control lever and cable. Make sure that

the cable is free and that the lever is not

damaged. Also check the cable linkage

running to the carburetor for kinks, loose

fittings, and obstructions. Verify that the

control bail is working properly.

19. Stop the rotating trimmer head when

crossing gravel drives, walks, or roads.

Wait for the cutting lines to stop rotating.

20. Watch for traffic when operating near, or

when crossing roads.