9

Case LB334/434 & New Holland Big Baler Series (MY2020 and Prior) (continued)

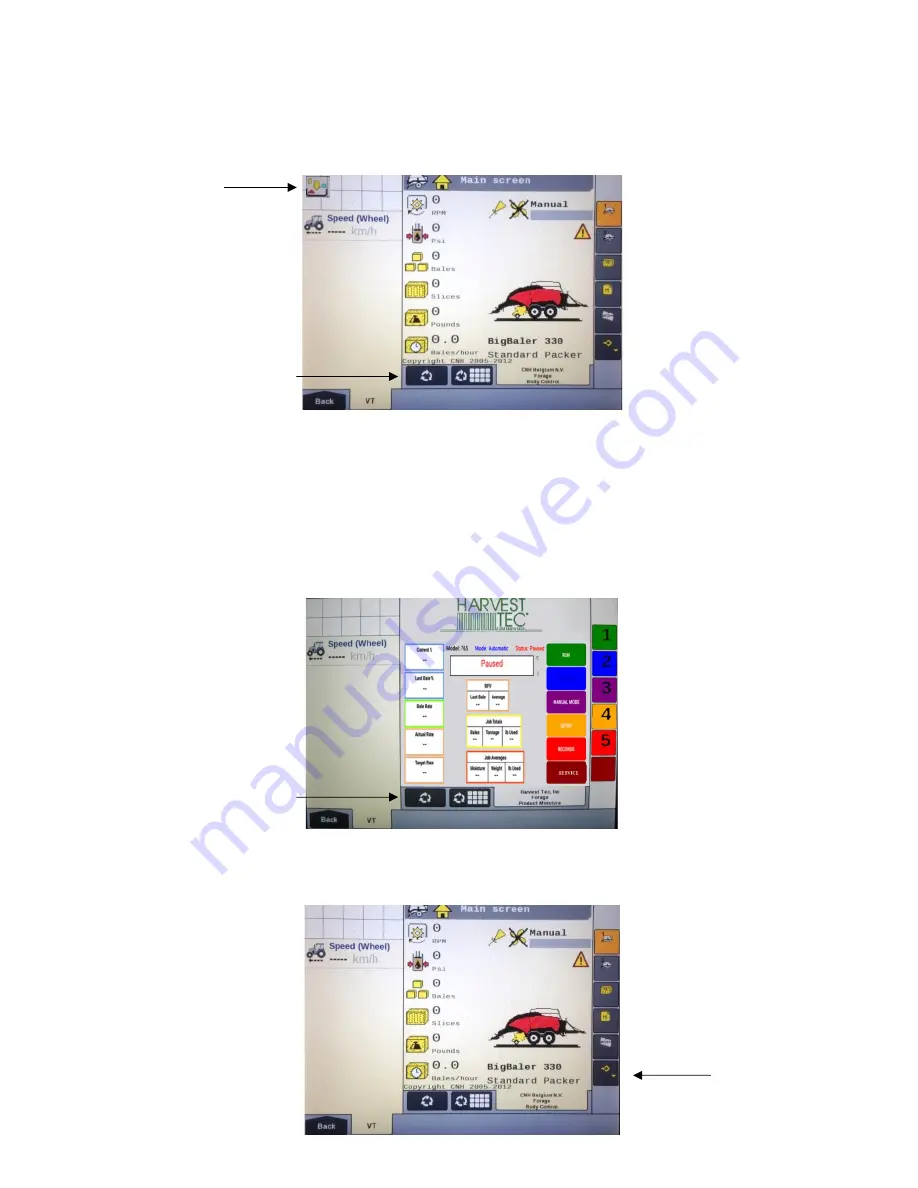

Icon (1) indicates that the object pools are in the process of loading and saving to the VT. Note that if the

language selection of the VT is changed, the corresponding object pool must be reloaded to the VT. The

object pool loading process takes approximately two minutes to complete.

Once the object pools have been loaded and Icon (1) disappears from the upper left corner of the display,

press the NEXT IMPLEMENT button (2) and verify that the moisture system object pool appear on the Virtual

Terminal.

After verifying that the moisture system object pool is loaded and the operating screens are displayed on the

VT, press the NEXT IMPLEMENT button (3) to return to the baler work screen page.

Press the bottom button of the Menu Bar with the down arrow in corner (4) on the side of the screen to

continue down the Menu Bar below the USER SETTING icon.

2

4

1

3

6