MACH

®

Gas Fired Boiler

34

3.11 B

URNER

A

DJUSTMENT

NOTICE! Adjustments shall only be performed by service representative specifically trained and certified

to perform maintenance on the Harsco Industrial, Patterson-Kelley MACH

®

boiler. Verify proper

operation after servicing.

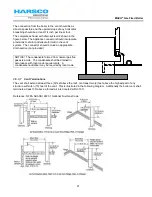

See rating plate for the minimum and maximum inlet gas pressure of

the boiler. The supply pressure during main burner operation must

be greater than the minimum indicated on the rating plate. Nominal

gas supply pressure is 7” W.C. for natural gas. The gas pressure

must not exceed 14” W.C. which is the maximum allowable pressure

on the gas train components.

Each boiler is furnished with a manual

shut-off valve which has an integrated test port. This port is located

on the upstream side of the valve body for measuring supply

pressure. (Seefigure right.)

The air flow is pre-set at the factory prior to shipment. Gas flow is

dependent primarily on fan speed not upstream gas pressure. The

air/gas ratio may have to be adjusted to obtain proper combustion

readings for specific local conditions. A combustion analyzer must be used. The probe must be place in the boiler

exhaust vent immediately after the boiler. Combustion should be adjusted in accordance with Table of Combustion

Exhaust Settings.

NOTICE! For high altitude adjustments (greater than 2,000 feet above sea level), see Appendix 2 at the

end of this manual.

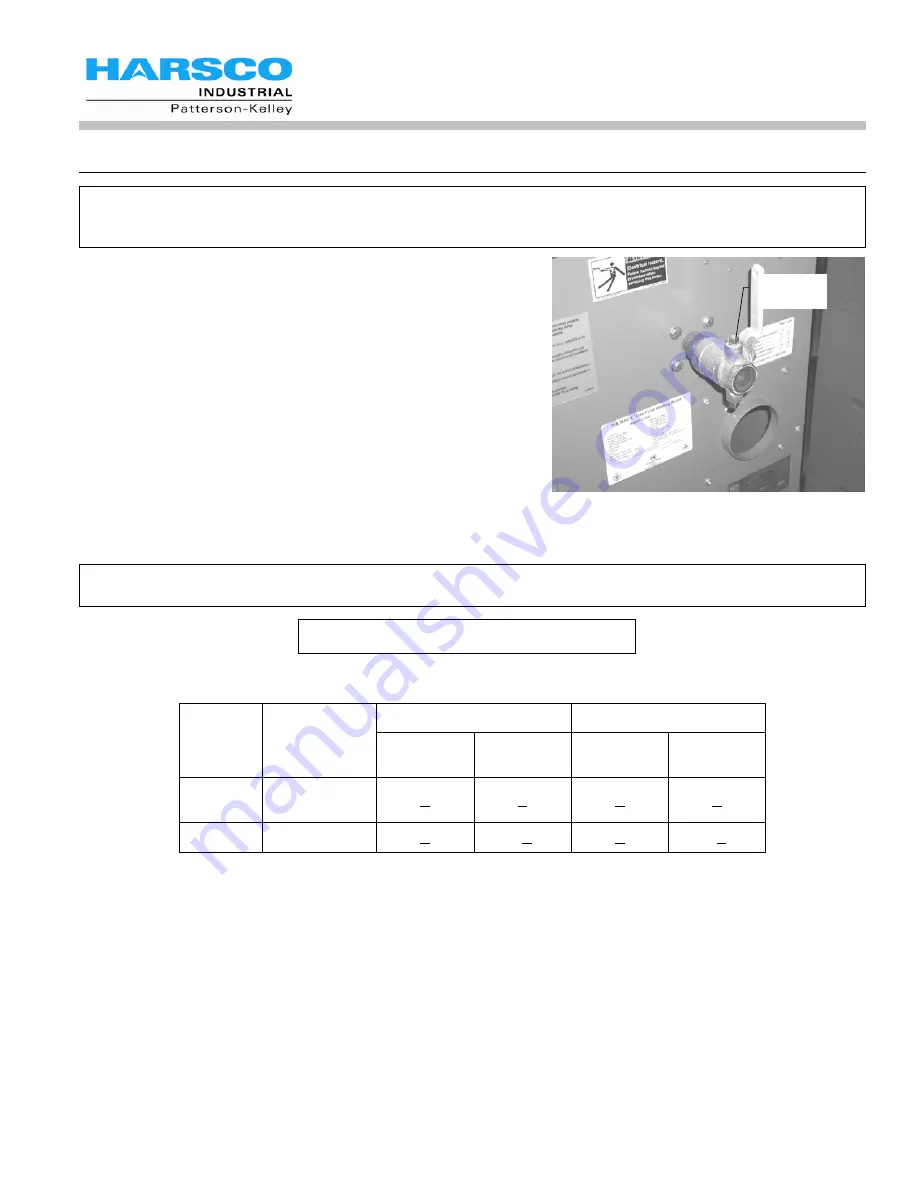

Fuel

Nominal

High Fire Setting

Low Fire Setting

Inlet Gas

Pressure*

% O

2

% CO

2

% O

2

% CO

2

Natural

Gas

7" W.C

5.0 + 0.2

9.0 + 0.2

5.2 + 0.2

8.8 + 0.2

Propane

11" W.C

5.0 + 0.2

10.4 + 0.3

5.2 + 0.2

10.3 + 0.3

Inlet Gas

Test Port

Table of Combustion Exhaust Settings