MACH

®

Gas Fired Boiler

13

•

Category IV

An appliance that operates with a positive vent static pressure and with a vent temperature that

may cause excessive condensate production in the vent.

•

Direct Vent

An appliance that is constructed and installed so that all air for combustion is derived directly

from outdoors and all flue gases are discharged to the outdoors.

3.5.1.2

Venting Materials for Flue/Exhaust Systems

The MACH

®

C750, C900 and C1050 boilers are dual-certified as both Category II and Category IV appliances, which

vent with a temperature that is likely to cause condensation in the vent. Refer to Section 3.5.3.2 for requirements of

Category II installations and Section 3.5.3.3 for requirements of Category IV installations. Any venting system used

with the MACH

®

boiler must comply with the applicable venting system category as specified in the latest edition of

NFPA 54/ANSI Z223.1 in the US or the latest edition of CAN/CSA B-149.1 in Canada.

The venting materials listed below are intended for the venting of gas burning appliances only. Do not

use these venting materials for venting liquid or solid fuel (such as oil, kerosene, wood or coal)

appliances.

Maintain clearances to combustibles as listed in the vent manufacturer’s installation instructions or as set

forth in the codes and standards listed in this section.

Do not use these vent pipes for incinerators of any sort.

This boiler is not certified for use with PVC venting. Use of PVC vent may

result in vent failure and possible serious injury or death.

According to ANSI Z21.13,/CSA 4.9, Gas-Fired Low Pressure Steam and Hot Water Boilers, Table XVII

“Maximum Allowable Temperatures of Typical Non-Metallic Vent Material” the maximum allowable

temperature for PVC is 158°F (70°) and for CPVC is 210°F (100°C).

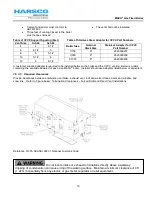

Table of Acceptable Materials for Venting Systems

Manufactured Venting

US and Canada

Factory Fabricated Metallic Vent Systems listed and labeled to UL1738 (Titled:

Venting Systems for Gas-

Burning Appliances, Categories II, III, and IV)

Non-metallic Venting

Within the US

CPVC pipe conforming to ASTM F441, fittings conforming to ASTM F439 (Sch 80). Joints are to be sealed

with solvent conforming to ASTM F493.

Within Canada

CPVC Pipe, Fittings and Sealant listed and labeled to ULC S-636

Standard for Type BH Venting Systems

Table 1.3.2 Applicable Vent Materials By Boiler Model

As per ANSI Z21.13b-2012 * CSA 4.9b-2012:

* The use of cellular core PVC, CPVC and Radel as venting materials is prohibited.

* The use of external insulation on plastic vent pipe is prohibited.