6 - Maintenance

85

Occasional maintenance

General info

The maintenance and renewal intervals for the following will depend very much on the conditions under which the sprayer

will be operated and are therefore impossible to specify.

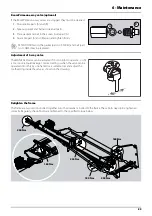

Pump valves and diaphragms renewal

Model pump:

Diaphragm pump overhaul kit (valves, seals, diaphragms etc.) can be

ordered. Detect the pump model - kit can be ordered at following

HARDI part No.:

Valves

Remove valve cover (1) before changing the valves (2) - note their

orientation so they are replaced correctly!

μ

ATTENTION! A special valve with white flap (2A) is used at the two

upper side inlets. It has to be placed in the valve openings as

shown. All others are the type with black flap. It is recommended

to use new gaskets (3) when changing or checking the valves.

Diaphragms

Remove the diaphragm cover (4). The diaphragm (5) may then be

changed. If fluids have reached the crankcase, re-grease the pump

thoroughly. Also check that the drain hole at the bottom of the pump is

not blocked. Reassemble with the following torque setting.

Reassemble pump model with the following torque setting.

Diaphragm cover: 90 Nm / 66.6 lbft

Diaphragm bolt: 90 Nm / 66.6 lbft

μ

ATTENTION! Before tightening the 4 bolts for the diaphragm cover (B) the diaphragm must be positioned between

centre and top to ensure correct sealing between diaphragm pump housing and diaphragm cover. Turn crank shaft

if necessary.

Содержание NAVIGATOR DELTA

Страница 4: ...1 EC Declaration 4 ...

Страница 10: ...Table of Contents 10 ...

Страница 14: ...2 Safety notes 14 ...

Страница 32: ...3 Description 32 ...

Страница 54: ...4 Sprayer setup 54 ...

Страница 74: ...5 Operation 74 ...

Страница 76: ...6 Maintenance 76 Boom lubrication oiling plan ...

Страница 77: ...6 Maintenance 77 Trailer lubrication oiling plan P T O lubrication oiling plan Serie 100 type P T O shaft C 50 ...

Страница 104: ...7 Fault finding 104 ...

Страница 120: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...