6 - Maintenance

80

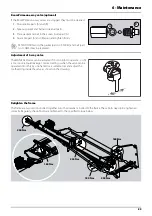

50 hours service - Wheel nuts

Tighten wheel nuts as follows with following torque wrench settings:

Wheel hub to rim plate: 490 Nm (362 lbft)

Tightening sequence: See illustration and tighten in order of

numbering.

μ

ATTENTION! When wheels has been mounted or re-tightened,

the plastic nut covers must be placed on the nuts afterwards.

50 hours service - Air brakes (optional)

The air brakes are checked for leaks by following procedure:

1.

Connect the snap couplers to the tractor and fill the trailer air tanks.

2.

Check for leaks with brakes released.

3.

Apply the brake up to full pressure.

4.

Check for leaks with brakes applied.

50 hours service - Tyre pressure

Check the tyre pressure according to the table in “Technical specifications”.

€

DANGER! Never inflate tyres more than to the pressure specified in the table. Over-inflated tyres can explode and

cause severe personal injuries! See the part “Occasional maintenance - Change of tyre”.

±

WARNING! If renewing tyres always use tyres with min. load index as specified.

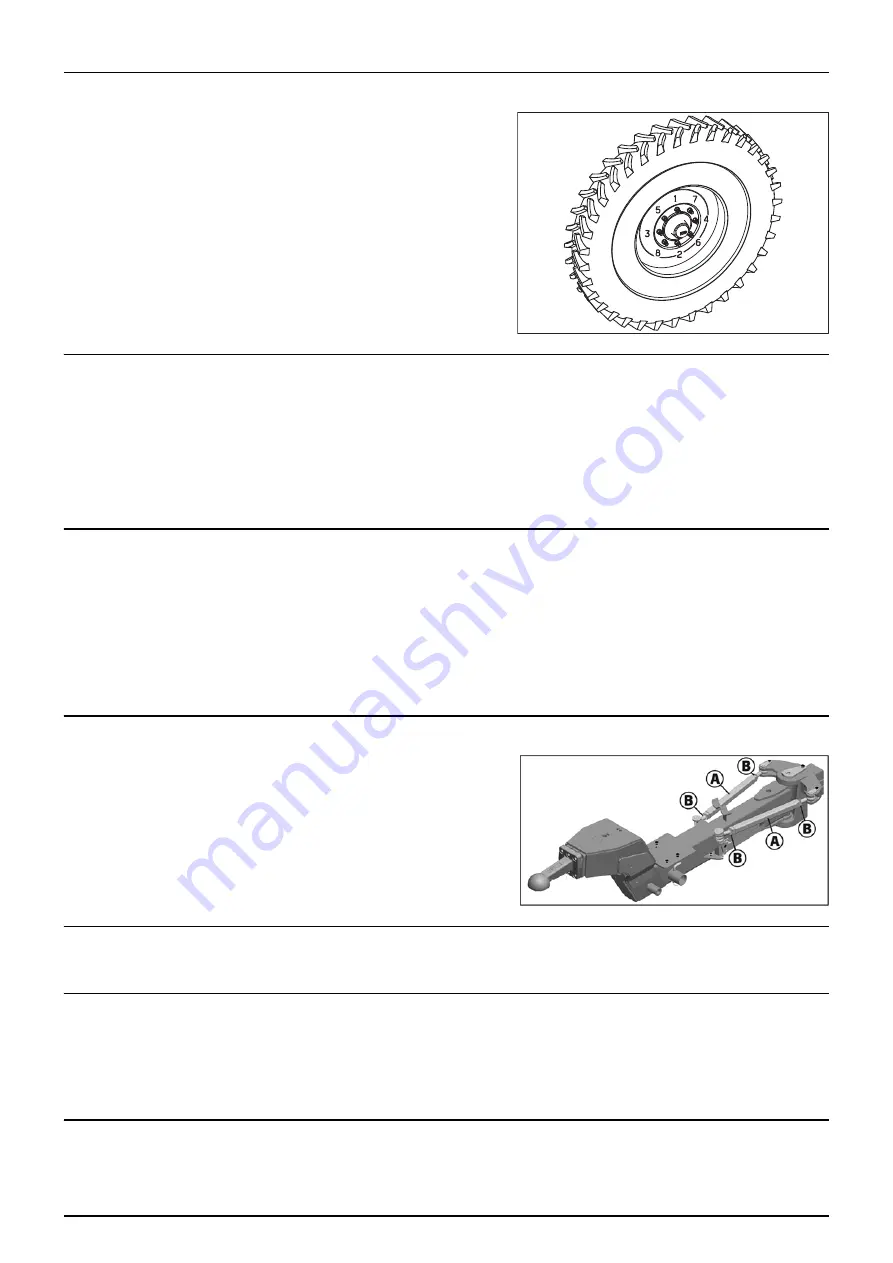

100 hours service - Check/adjust drawbar (Fixed high drawbar only)

If too much play is found in the lateral movements of the drawbar it

must be adjusted.

1.

Loosen counternuts (B).

2.

Regulate on the turnbuckles (A) on each side to adjust and centre

the drawbar.

3.

Tighten counternuts (B) again.

250 hours service - Readjustment of the boom

See section “Occasional maintenance” on page 85.

250 hours service - Hydraulic circuit

Check the hydraulic circuit for leaks and repair if any.

±

WARNING! Hoses for boom lifting device must be changed after every 5 years of use.

250 hours service - Hoses and tubes

Check all hoses and tubes for possible damage and proper attachment. Renew damaged hoses or tubes.

Содержание NAVIGATOR DELTA

Страница 4: ...1 EC Declaration 4 ...

Страница 10: ...Table of Contents 10 ...

Страница 14: ...2 Safety notes 14 ...

Страница 32: ...3 Description 32 ...

Страница 54: ...4 Sprayer setup 54 ...

Страница 74: ...5 Operation 74 ...

Страница 76: ...6 Maintenance 76 Boom lubrication oiling plan ...

Страница 77: ...6 Maintenance 77 Trailer lubrication oiling plan P T O lubrication oiling plan Serie 100 type P T O shaft C 50 ...

Страница 104: ...7 Fault finding 104 ...

Страница 120: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...