19

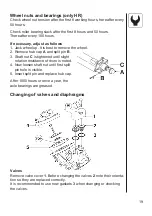

Wheel nuts and bearings (only HR)

Check wheel nut tension after the first 8 working hours, hereafter every

50 hours.

Check roller bearing slack after the first 8 hours and 50 hours.

Thereafter every 100 hours.

If necessary, adjust as follows

1. Jack wheel up. It is best to remove the wheel.

2. Remove hub cap A and split pin B.

3. Shaft nut C is tightened until slight

rotation resistance of drum is noted.

4. Now loosen shaft nut until first split

pin hole is visible.

5. Insert split pin and replace hub cap.

After 1000 hours or once a year, the

axle bearings are greased.

Changing of valves and diaphragms

Valves

Remove valve cover 1. Before changing the valves 2 note their orienta-

tion so they are replaced correctly.

It is recommended to use new gaskets 3 when changing or checking

the valves.

Содержание Boss Series

Страница 1: ...BOSS HERON Instruction book 673791 GB 04 2002 www hardi international com...

Страница 18: ...16 1 X 40 2 A X 8 A X 40 3 X 40 17 6 9 T200 0001...

Страница 19: ...17 4 X 40 5 X 40 X 1000 or once a year 16 16 HR only...

Страница 47: ...45 1202 foot A10...

Страница 48: ...46 A12 1302 foot...

Страница 49: ...47 Unit BK 180K 92 B9...

Страница 50: ...48 B10 Distributor BK180K 92...

Страница 51: ...49 Damper HJ73 B300...

Страница 52: ...50 D2 SB 6 8 10 m...

Страница 53: ...51 Boom tube TRIPLET SNAP FIT D904...

Страница 54: ...52 H106 PS 300...

Страница 55: ...53 TPS 800 H107...

Страница 56: ...54 H108 PU TPS 800...

Страница 58: ...56...

Страница 60: ...HARDI INTERNATIONAL A S Helgesh j All 38 DK 2630 Taastrup DENMARK...