Page 8

For technical questions, please call 1-800-520-0882.

Vertical Engine

Set Up

Model 68123

: The emission control system for this

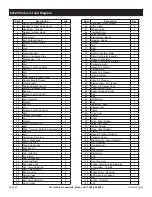

engine is warranted for standards set by the U.S.

Environmental Protection Agency. For warranty

information, refer to the last pages of this manual.

Models 68122:

The emission control system for this

Generator’s Engine is warranted for standards set by the

U.S. Environmental Protection Agency and by the California

Air Resources Board (also known as CARB). For warranty

information, refer to the last pages of this manual.

Read the ENTIRE IMPORTANT SAFETY

INFORMATION section at the beginning

of this manual including all text

under subheadings therein before

set up or use of this product.

TO PREVENT SERIOUS INJURY:

Operate only with proper spark arrestor installed.

Operation of this equipment may create sparks that

can start fires around dry vegetation.

A spark arrestor may be required.

The operator should contact local fire agencies for laws

or regulations relating to fire prevention requirements.

At high altitudes, the engine’s carburetor, governor (if so

equipped), and any other parts that control the fuel-air

ratio will need to be adjusted by a qualified mechanic to

allow efficient high-altitude use and to prevent damage to

the engine and any other devices used with this product.

1.

IMPORTANT:

If you have any doubts about your

ability to perform the following procedures, have a

qualified service technician perform the installation.

2. Install this engine on a lawn mower only.

3. Set the Engine upright on the mower, and align at

least three 3/8” diameter coarse threaded engine

mounting holes with mower mounting holes.

NOTE:

Depending on the mower, it may be necessary

to drill mounting holes or make a mounting plate

to align with the engine mounting holes. Only a

qualified technician should attempt these solutions.

4. Use 3/8” diameter, coarse threaded, hardened,

stainless steel Bolts, Lock Washers, and Washers (not

included) of appropriate length to secure the Engine to

the mower.

Make sure the hardware does not

contact moving parts.

5. Insert the mower’s brake cable sheath through the

hole in the Brake bracket. Secure the mower brake

cable to the brake arm. Adjust the brake cable sheath

to remove all slack and secure it in place using the

adjusting nuts on the cable sheath, as shown in the

illustration below.

THE ENGINE BRAKE IS FOR EMERGENCY

SHUTOFF; DO NOT REPLACE THE BRAKE SPRING

WITH A WEAKER SPRING. If operating the engine

brake is too difficult, a qualified technician must

install a different brake handle on the mower.

Note:

The brake cable on some mowers may

need to be adjusted in a different manner. Install

according to mower manufacturer’s instructions.

6.

Brake

Arm

Choke

Brake

Cable

Brake

Cable

Bracket

Choke

Cable

Bracket

and

Bolt

Attach the end of the mower’s Choke Cable

to the Choke. Use the Bracket and Bolt to

secure its sheath in place as shown above.

7. This engine is set to a single speed

that should not be adjusted.

8. Refer to the mower’s service manual for instructions

on how to properly attach a belt drive pulley, chain

drive gear, etc. onto the output shaft of the Engine.