Page 14

For technical questions, please call 1-800-520-0882.

Vertical Engine

Spark Plug Maintenance

1.

Spark

Plug

Cap

Disconnect spark plug cap from end of plug.

Clean out debris from around spark plug.

2. Using a spark plug wrench, remove the spark plug.

3. Inspect the spark plug:

If the electrode is oily, clean it using a clean, dry

rag. If the electrode has deposits on it, polish it

using emery paper. If the white insulator is cracked

or chipped, the spark plug needs to be replaced.

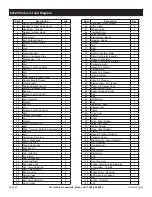

Recommended Spark Plugs

Brand

Plug

NGK

®

BP-6ES/BPR6ES

NHSP

® /

TORCH

®

F7TC/F7RTC

DENSO

®

W16EPR-U/W16EP-U

CHAMPION

®

RN9YC4

NOTICE:

Using an incorrect spark

plug may damage the engine.

4. When installing a new spark plug, adjust the

plug’s gap to the specification on the Technical

Specifications chart. Do not pry against the

electrode, the spark plug can be damaged.

5. Install the new spark plug or the cleaned spark plug

into the engine. Gasket-style: Finger-tighten until the

gasket contacts the cylinder head, then about 1/2-2/3

turn more.

Non-gasket-style: Finger-tighten until the plug

contacts the head, then about 1/16 turn more.

NOTICE:

Tighten the spark plug properly. If

loose, the spark plug will cause the engine

to overheat. If overtightened, the threads

in the engine block will be damaged.

6. Apply dielectric spark plug boot protector

(not included) to the end of the spark plug

and reattach the wire securely.

Storage

When the equipment is to remain idle for longer than

20 days, prepare the engine for storage as follows:

1.

CLEANING

:

Wait for engine to cool, then clean engine with

dry cloth.

NOTICE:

Do not clean using water.

The water will gradually enter the engine and cause

rust damage.

Apply a thin coat of rust preventive oil to all metal parts.

2.

FUEL:

WARNING!

TO PREVENT SERIOUS

INJURY FROM FIRE:

Drain the fuel tank in a well-ventilated area

away from ignition sources. If the engine is

hot from use, shut the engine off and wait for it

to cool before draining fuel. Do not smoke.

a. Place a funnel leading to a proper gasoline

container below the carburetor.

b.

Drain Plug

Remove the drain bolt from the bottom of the

carburetor bowl and allow the fuel to drain.

c. After all fuel has drained, reinstall the

drain bolt. Tighten securely.

3.

LUBRICATION:

a. Change engine oil.

b. Clean out area around spark plug. Remove

spark plug and pour one tablespoon of engine

oil into cylinder through spark plug hole.

c. Replace spark plug, but leave spark

plug cap disconnected.

d. Pull Starter Handle to distribute oil in cylinder.

Stop after one or two revolutions when you

feel the piston start the compression stroke

(when you start to feel resistance).

4.

STORAGE AREA:

Cover and store in a dry, level, well-ventilated

area out of reach of children. Storage area should

also be away from ignition sources, such as

water heaters, clothes dryers, and furnaces.

5.

AFTER STORAGE:

Before starting the engine after storage, keep

in mind that untreated gasoline will deteriorate

quickly. Drain the fuel tank and change to fresh

fuel if untreated gasoline has been sitting for

a month, if treated gasoline has been sitting

beyond the fuel stabilizer’s recommended time

period, or if the engine does not start properly.