28

Step 7

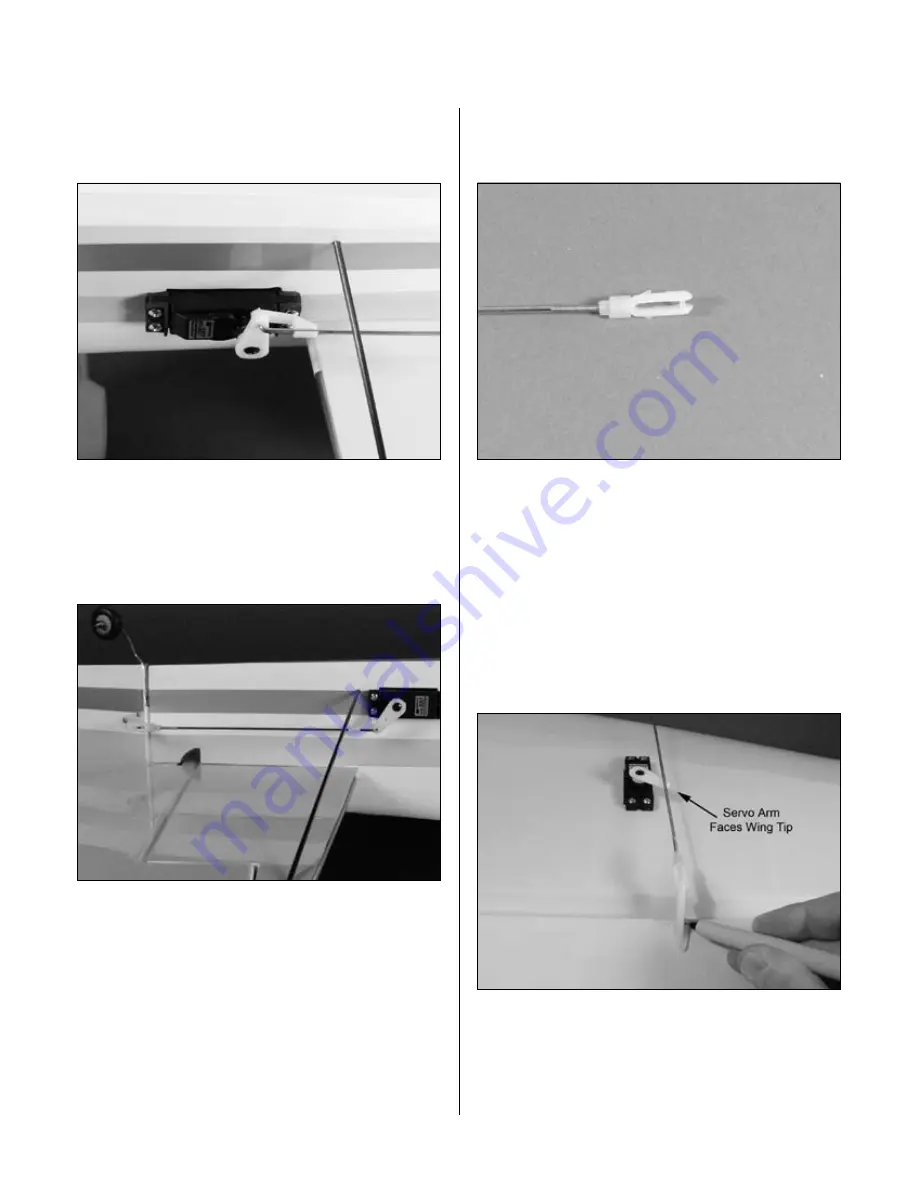

Slide the wire through the outer hole in the elevator

servo arm. Secure the wire using a nylon wire keeper.

Step 8

Repeat Steps 1 through 7 for the rudder linkage. Before

marking the location of the control horn, use the radio

to deflect the rudder servo to its full throw. The pushrod

will be parallel to the stabilizer for the correct geometry.

Step 9

Slide a clevis retainer onto a nylon clevis. Thread a clevis

onto a 7

7

/

8

" (200mm) wire a minimum of 10 turns.

Step 10

Remove the back plate from a control horn using side

cutters or a sharp hobby knife. Attach the clevis to

the control horn. After installing a heavy-duty servo

arm, position the control horn on the aileron so the

horn aligns with the hinge line of the aileron. With

the aileron servo deflected for full throw, position

the pushrod so it is perpendicular to the hinge line

as it crosses the servo arm. Mark the position for

the mounting holes using a felt-tipped pen.

Step 11

Drill three 1/16" (1.5mm) holes at the locations marked

in the previous step. The holes only need to be 3/4"

(19mm) deep: don’t drill through the top of the aileron.

Section 8: Servo Installation