Supplied By www.heating spares.co Tel. 0161 620 6677

FAULT FINDING

8

8.1

GENERAL

8.2

DIAGNOSTIC INDICATOR LED’S

8.3

START/POWER UP FAULTS

8.4

IGNITION FAULTS

8.5

DHW FAULT FINDING

8.6

CENTRAL HEATING FAULT FINDING

Before looking for a fault condition, check that:

The mains electrical supply is turned on.

The clock and / or room thermostat (if fitted) are calling for heat

(CH ‘faults’ only)

The gas service cock is open.

The DHW and CH isolation cocks are open.

The system is at design pressure.

Before attempting any electrical fault finding, always conduct the

preliminary electrical system checks as described in the

Instructions for the British Gas Multimeter or other similar

instrument.

On completion of any service or fault finding operation involving

making or breaking electrical connections always check for EARTH

CONTINUITY, POLARITY, and RESISTANCE TO EARTH.

Detailed procedures for replacing faulty components are

described in section 9 (Parts Replacement)

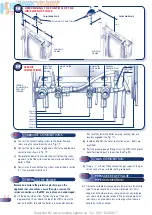

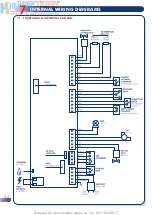

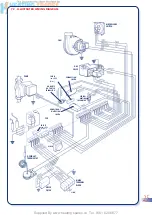

The LED’s on the fascia panel (Fig. 31) show the status of the

boiler as described below:

Power

ON

LED illuminated. (Green): Boiler is in service. If no

other LED’s are illuminated, the appliance is awaiting a demand

for heating or hot water.

Burner

ON

LED illuminated (Amber): Burner is alight.

Safety Lockout LED flashing (Red): Burner has failed to light and

gone to ignition lock-out. Re-set the appliance by disconnecting

the power supply (or turning off the CH/DHW heat demand)

waiting 10 seconds, and restoring the power (or demand).

Safety Lockout LED illuminated (Red): There is a fault condition

preventing operation of the appliance. Follow fault finding

procedure.

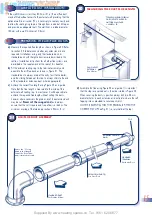

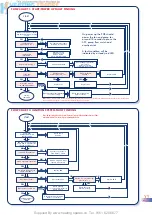

When the power is first turned on The pump and fan will operate

for 10 to 15 seconds whilst the controls check the operation of the

air pressure switch, the water flow switch, and the overheat

thermostat. If any of these are not operating correctly the Safety

Lock-out LED will be illuminated.

In the event of a power up fault investigate the problem by

following flow chart 1.

In the event of the boiler failing to light, investigate the problem

by following flow chart 2.

When the hot water tap is turned on, the controls should carry out

a set of start up checks (flow chart 1) followed by an ignition

sequence (flow chart 2)

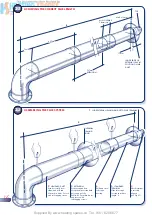

If the control has powered up correctly but does not respond to a

DHW demand, investigate in the following order:

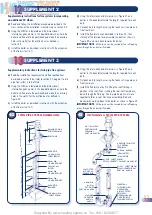

Check for 0V d.c. across pins 23 and 24. If 5V is present across

pins 23 and 24 check water flow switch and wiring.

If 0V is present, check DHW thermistor and wiring. If DHW

thermistor and wiring are OK, replace PCB.

If burner lights and remains lit, but fails to modulate correctly:

Check voltage at modureg valve, pins 30 and 31. Voltage should

be in the range 2.5 - 20V d.c. (During ignition, voltage should be

approx 10V d.c.). If outside this range, check DHW thermistor and

wiring, If DHW thermistor and wiring are OK, replace PCB.

If modureg voltage varies with temperature but burner pressure

remains constant replace gas valve.

Upon a demand for Central Heating, (closure of the room

thermostat and time switch if fitted) the appliance should respond

to the demand.

If the control does not respond to a CH demand, investigate in

the following order:

If a time switch is not fitted, ensure that the link is in the ‘no clock’

position.

If 240V a.c. is present across pins 2 and 4 but no start up

procedure occurs ensure that the control is not in anti-cycle mode

by removing power from the control and restoring it after a delay

of 10 seconds.

If the control still does not carry out start up checks,

Check CH thermistor and wiring. If CH thermistor and wiring are

OK, replace PCB.

If burner lights and remains lit, but fails to modulate correctly:

Check voltage at modureg valve, pins 30 and 31. Voltage should

be in the range 2.5 - 20V d.c. (During ignition, voltage should be

approx 10V d.c.). If outside this range, check CH thermistor and

wiring, If CH thermistor and wiring are OK, replace PCB.

If modureg voltage varies with temperature but burner pressure

remains constant replace gas valve.

Note: Whenever a CH demand is removed, either by the timer,

the room thermostat or the boiler internal temperature

control, an anti cycle mode is initiated which prevents the

boiler firing in CH mode for 3 minutes.

26