4

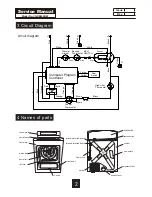

3) Power transmission system

During drying, Motor 1 transmits the driving power to Tumbler 5 through Belt 2 and

Multi-wedge belt 3. Then Tensioning wheel 4 tensions the belt under the action of

tensioning spring. At the same time, it also increases the transmission wrap angle of the

pulley, and improves the transmission efficiency of the belt. The motor rotates to one

single direction during drying. The tumbler will also rotate to one single direction. The

motor is centrifugal type, and has acquired the UL certification, with strong driving power

and long operation life.

4) Air intake and exhaust system

The appliance collects air through shutter, and heats the air with electric heating thread. The air

exhaust system composed of volute impellers generates negative atmosphere pressure under the suction

force, and thus attracts the hot air into the tumbler to dry the laundries. The air intake and exhaust system

has high degree of tightness, and improves the thermal efficiency.

5) Heating system

The electric heating thread installed on the heating plate at the rear of the cabinet, is the heating

source of the appliance. The exchanging of cold and hot air is realized by it. The heating power of the

electric heating thread is about 4700W. It can raise the air temperature rapidly, and offer hot air continuously.

2

1

4

3

5

Rotation direction

2) Temperature sensor

The temperature sensor of this appliance has also acquired the UL certification. It acts as nerve

center during usage of the appliance. It is used to detect the dry degree or temperature, and can effectively

prevent the defects like the crimple of laundries owing to overheating.

1) Program control

As the control center of the appliance, the program controller directs the appliance to meet the

demand of the user like the brain of human body. This part has acquired the UL certification, with long

operation life and reliable performance.

C

Product briefs

6 Product Brief and New Features

Service Manual

Model No. CGDE480BW

Issue

Rev.