28

28

A.

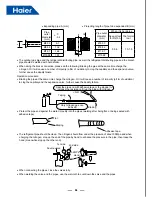

Refrigerant pipe connection

Pipe connection method

■

To ensure the efficiency, the pipe should be as short as

possible.

■

Daub the refrigerant oil on the connector and the flare nut.

■

When bending the pipe, the bending semi-diameter should be

as large as possible against the pipe being broken or bent.

■

When connecting the pipe, aim at the center to thread the nut

by hand and tighten it with the double spanners.

■

Fastening torque please refers to "pipe specs and fastening

torque" on page 15.

■

Don't let the impurity such as sand, water etc into the pipe.

Antifouling measures refer to page 13.

■

When fastening and loosing the nut, operate

with double spanners, because only one

spanner cannot execute firmly.

■

Spanner

■

Spanner

■

Nut

■

Connector

■

If threading the nut as not aiming at the

center, the screw thread will be damaged,

further it will cause leakage.

Cautions in piping installation:

■

When welding the pipe with hard solder, charge nitrogen into the pipe against oxidation. The pressure

gauge

should be set at 0.02 MPa. Perform the procedure with nitrogen circulation. Otherwise, the

oxide film in the pipe

may clog the capillary and expansion valve resulting in accident.

■

The refrigerant pipe should be clean. If the water and the other impurity enter the pipe, charge the nitrogen to

clean the pipe. The nitrogen should flow under the pressure of about 0.5Mpa and when charging the nitrogen,

stop up the end of the pipe by hand to enhance the pressure in the pipe, then loose the hand (meanwhile stop up

the other end).

■

The piping installation should be executed after the stop valves are closed.

■

When welding the valve and the pipe, cool down the valve with wet towel.

■

When the connection pipe and the branch pipe need to be cut down, please use the special shears and cannot

use the saw.

■

When welding copper pipe, use the phosphor copper welding rod without any welding flux.

■

(welding flux will damage the piping system. The welding flux containing chlorine will corrode pipe, especially, the

welding flux with fluorin will damage refrigeration oil.)

Pipe material and specs selection

■

Please select the refrigerant pipe of the below material.

■

Material: the phosphoric oxidize seamless copper pipe, model: C1220T-1/2H (diameter is over 19.05); C1220T-0

(diameter is below 15.88).

■

Thickness and specs:

■

Confirm the pipe thickness and specs according to the pipe selection method (the unit is with R410A, if the pipe

over 19.05 is 0-type, the pressure preservation will be bad, thus it must be 1/2H type and over the min.

thickness.)

■

The branch pipe and the gather pipe must be from Haier.

■

When installing the stop valve, refer to the relative operation instruction.

■

The pipe installation should be in the allowable range.

■

The installation of branch pipe and gather pipe should be performed according to the relative manual.

Содержание AV08NMSETA

Страница 1: ...SYJS 11 2016 REV A Edition 2016 11 Service Manual MRV SII ...

Страница 15: ...13 13 Dimension 4 Dimension 1050 D ...

Страница 25: ...23 23 Outdoor Installation Multi Outdoor Min300mm Min300mm Min360mm Min300mm Inlet Outlet h A ...

Страница 53: ...51 51 Dip Switch Setting 11 Dip Switch Setting Outdoor PCB photo BM2 SW1 SW2 SW3 SW4 LED3 LED1 BM1 LED2 LED4 ...