ES0755 rev A 1/11

27

1. With no tool in the machine, command a tool change. Press Emergency Stop before the double arm

reaches the spindle. This will cause the mill to move the Y and Z axes to the ATC position.

2. Verify the spindle is free to rotate without hitting the double arm. If necessary, use the T/C Recovery

commands to move the arm further from the spindle.

3. Using T/C Recovery, orient the spindle.

4. Using T/C Recovery, rotate the double arm in the forward direction. Continue rotating the double arm until it

reaches the spindle, then extends approximately 6” (152.4 mm) in front of the spindle.

5. Using the dowel pin as a handle, install the tapered half of the split tool into the spindle. Be careful to not

place your hands in the pinch point between the tool and the spindle. The Tool Release button operates in a

Toggle On/Off mode during Tool Recovery. Press once to activate the Tool Release; press again to clamp.

6. Remove the dowel pin, and install the second half of the split tool into the end of the double arm in front of

the spindle. It will be necessary to manually press the tool lock plunger (near the center of the shaft as shown

in the Service manual) to allow the spilt tool to be inserted.

7. Using T/C Recovery in the reverse direction, move the double arm back toward the spindle until the halves

of the split tool are approximately 1” (25.4 mm) apart.

8. Continue to move arm toward spindle. Watch double arm as it approaches spindle. The spindle dogs and

slots in the double arm should line up. This verifies Parameter 257 (Spindle Orient Offset). If spindle and arm

do not line up, reset Parameter 257 as described in Service Manual, and continue moving closer until there is

a maximum of 1/8” (3.2 mm) gap between the split tool halves, ensuring the halves do not touch each other.

9. Check the X and Y alignment of the double arm to the spindle by inserting the alignment dowel through

both halves of the split tool. The dowel should slide freely. If the pin does not slide freely, the direction of the

misalignment may be determined by feeling the “step” between the split tool halves, by using a steel rule,

straight edge, or similar tool.

10. If misalignment is present, adjust the leveling screw under the tool changer mount. Verify machine level

before continuing.

11. Using T/C Recovery, move the double arm in the forward direction, away from the spindle. Remove both

halves of the split tool.

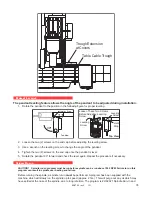

12. Install a tool holder into the double arm, measure the distance from the front of the double arm to the front

face of the tool holder (see diagram), and record the distance.

Measure the distance from the

surface of the double arm to

the surface of the tool holder

A

6

5

1

2

3

4

5

6

7

8

8

9

9

1

Made in America

Tool Changer

Double Arm

Tool Holder

Measure This

Distance

80

7

0

6

0

90

0

5

0

40

30

2

0

1

0

13. Remove the tool from the double arm. Using T/C Recovery, move the arm in the reverse direction to the

spindle. Continue until the arm rotates to the origin “Home” position. Once the arm is away from the spindle,

insert the same tool holder used in Step 13 into the spindle.

14. Using T/C Recovery, rotate arm forward until it is very close to the tool holder. The spring-loaded slide is

depressed as arm nears the tool holder, but be sure that arm is not touching the tool holder itself.