Filling the Water Heater

Do not insert the power cord into the electrical receptacle until

all the following steps have been completed.

Make sure the drain valve is closed.

Open a nearby hot-water faucet served by the system to

allow air to escape from the tank.

Open the cold-water inlet valve.

Note:

When filling, avoid water leakage. Do not allow

the insulation of the water heater to get wet as water

can reduce the effectiveness of the insulation.

When an uninterrupted stream of water, without apparent

air bubbles, flows from the open hot-water faucets, the

tank is full.

Close the hot-water faucets and check the system for

leaks. Repair as required and retest.

Please note the following:

The system should be installed only with piping that is suitable

for potable (drinkable) water.

DO NOT

use any pumps, valves, or

fi

ttings that are not

compatible with potable water.

AVOID

use of valves that may cause excessive restriction to

water

fl

ow. Use full

fl

ow ball or gate valves only.

DO NOT

use any lead based solder in potable water lines.

Use appropriate tin-antimony or other equivalent material.

DO NOT

tamper with the gas control/thermostat, igniter,

fl

ammable vapour sensor or temperature and pressure relief

valve. Tampering voids all warranties. Only a quali

fi

ed service

technician should service these components.

DO NOT

use with piping that has been treated with chromates,

boiler seal, or other chemicals.

DO NOT

add any chemicals to the system piping which will

contaminate the potable water supply.

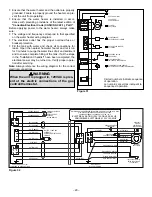

COLD WATER

INLET

COLD WATER

INLET VALVE

TEMPERATURE AND

PRESSURE RELIEF VALVE

HOT

WATER

OUTLET

UNION

DRAIN PAN CONNECT TO

PROPERLY OPERATING

FLOOR DRAIN.

DISCHARGE LINE 300mm

(12 in.) max ABOVE FLOOR

In a closed system use either:

1.THERMAL EXPANSION TANK

2.PRESSURE RELIEF VALVE.

NOTE: BLOWER

ASSEMBLY NOT

SHOWN FOR

CLARITY.

1

2

Figure 27

1.

2.

3.

4.

5.

COLD WATER

INLET

HOT

WATER

OUTLET

TEMPERING

VALVE (SET

TO 49°C

(120°F))

FOLLOW THE

TEMPERING

VALVE

MANUFACTURER'S

INSTRUCTIONS

T&P VALVE

AND

DISCHARGE

LINE

COLD W

ATER

TEMPERED

WATER T

O

FIXTURE

Figure 28

Closed System/Thermal Expansion

Water supply systems may, because of code requirements

or such conditions as high line pressure, among others, have

installed devices such as pressure reducing valves, check

valves, and back

fl

ow preventers. Devices such as these

cause the water system to be a closed system. As water is

heated, it expands (thermal expansion). In a closed system

the volume of water will grow when it is heated. As the volume

of water grows there will be a corresponding increase in water

pressure due to thermal expansion. Thermal expansion can

cause premature tank failure (leakage). This type of failure is

not covered under the limited warranty. Thermal expansion

can also cause intermittent Temperature-Pressure Relief Valve

operation: water discharged from the valve due to excessive

pressure buildup. This condition is not covered under the

limited warranty. The Temperature-Pressure Relief Valve is

not intended for the constant relief of thermal expansion. A

properly sized thermal expansion tank must be installed on

all closed systems to control the harmful effects of thermal

expansion. Contact a local plumbing service agency to have

a thermal expansion tank installed.

Important:

Do not plug or remove the temperature and

pressure (T&P) relief valve.

Temperature and Pressure (T&P) Relief

Valve

For protection against excessive pressures and temperatures,

a temperature and pressure relief valve must be installed in

the opening marked "T&P RELIEF VALVE" (see Figure 30).

This valve must be design certi

fi

ed to meet the requirements

of the

"Standard For Relief Valves For Hot Water Supply

Systems", ANSI Z21.22/CSA 4.4

. The function of the

temperature and pressure relief valve is to discharge water

in large quantities in the event of excessive temperature or

pressure developing in the water heater. The valve's relief

pressure must not exceed the working pressure of the water

heater as stated on the data plate.

– 18 –