Model T32006 (Mfd. Since 01/20)

-23

-

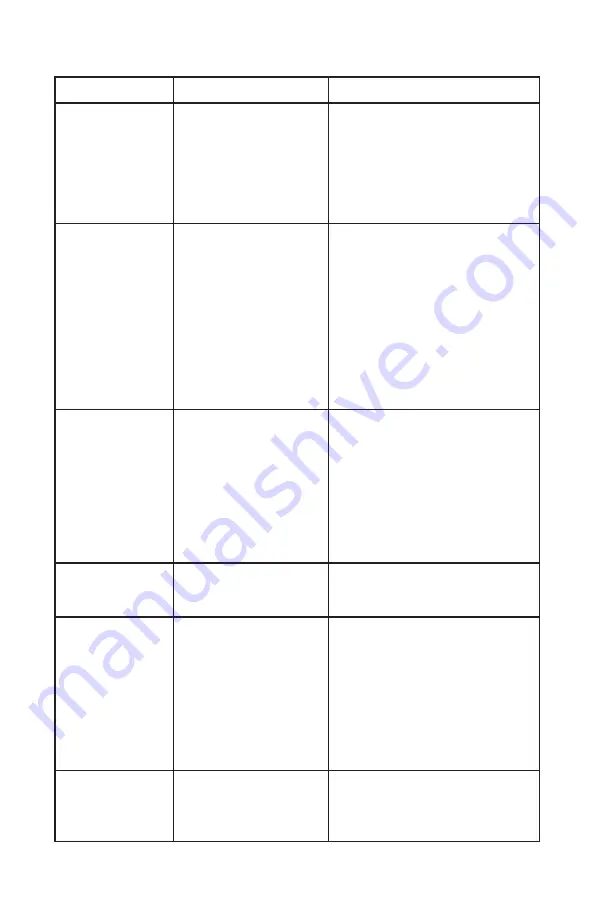

Symptom

Possible Cause

Solution

Tool falls out/loose

in spindle/chuck.

1. Tool loose or incorrectly

installed.

2. Debris on tool or in

spindle taper.

3. Taking too deep of a cut

without clearing chips.

1. Remove and re-install (

Page 17).

2. Clean contaminants from tool

and spindle taper, then re-install

(

Page 17).

3. Decrease depth of cut and allow

chips to clear.

Breaking tools or

bits.

1. Spindle speed/feed rate

too fast.

2. Taking too deep of a cut

without clearing chips.

3. Improper drilling tech-

nique or type of cut.

4. Bit/tool getting too hot.

5. Spindle extended too far

down while drilling.

1. Reduce spindle speed (

Page 19)

or feed rate.

2. Decrease depth of cut and allow

chips to clear.

3. Use right technique, tool, or

machine for job.

4. Use coolant or oil for appropri-

ate application (

Page 18); reduce

spindle speed (

Page 19).

5. Retract spindle and lower head-

stock to increase rigidity.

Workpiece or tool

vibrates or chatters

during operation.

1. Tool loose or incorrectly

installed.

2. Spindle extended too far

down while drilling.

3. Headstock height lock

not tight.

4. Workpiece not secure.

5. Spindle speed/feed rate

too fast.

1. Remove and re-install (

Page 17).

2. Retract spindle and lower head-

stock to increase rigidity.

3. Tighten lock (

Page 17).

4. Properly clamp workpiece.

5. Reduce spindle speed (

Page 19);

reduce feed rate.

Headstock is hard

to raise.

1. Headstock locked.

2. Column dirty.

1. Loosen headstock height lock

(

Page 17).

2. Clean column.

Poor work results

or tearout in holes.

1. Spindle speed/feed rate

too fast/too slow.

2. Dull or incorrect tool/bit.

3. Workpiece not secure.

4. Spindle extended too far

down while drilling.

5. Excessive chips left in

drill hole.

1. Adjust spindle speed (

Page 19)/

feed rate.

2. Sharpen/replace bit/tool or select

better tool for operation.

3. Properly secure workpiece.

4. Retract spindle and lower head-

stock to increase rigidity.

5. Retract drill bit frequently and allow

chips to clear.

Spindle overheats.

1. Spindle speed/feed rate

too fast.

2. Drill operated too long at

high speeds.

1. Reduce feed rate/cutting speed

(

Page 19).

2. Allow drill to cool, avoid operating

at high speeds for extended time.

Drilling Operations

Содержание T32006

Страница 32: ......