-24-

Model T32002 (Mfd. Since 02/20)

Below are some quick tips for getting the most out

of your buffing wheel. Remember, there is no sub-

stitute for experience. Learning how to hold the

workpiece, how much pressure to apply, and how

to move the workpiece against the wheel requires

a certain amount of trial-and-error.

•

Thoroughly clean all parts you plan to buff.

Dirt, oil, rust, paint, or other film must be

removed chemically or with water. Make sure

to dry off parts with a rag after cleaning.

Buffing

•

To begin buffing, slowly feed workpiece into

buffing wheel. Hold workpiece tightly at all

times while buffing. Placing one hand near

contact point will give you better control.

•

Wear safety equipment when buffing. If buffer

forces workpiece out of your hand, be pre-

pared for it to come flying at you! Wear safety

glasses or a face shield and a heavy leather

apron. Also, wear a dust mask to protect your

lungs from microscopic particulate that will be

flying off wheel.

Use caution when polishing plated metals;

there is a chance that thinly-plated materials

could be damaged. Light pressure is all that

is needed for quality work.

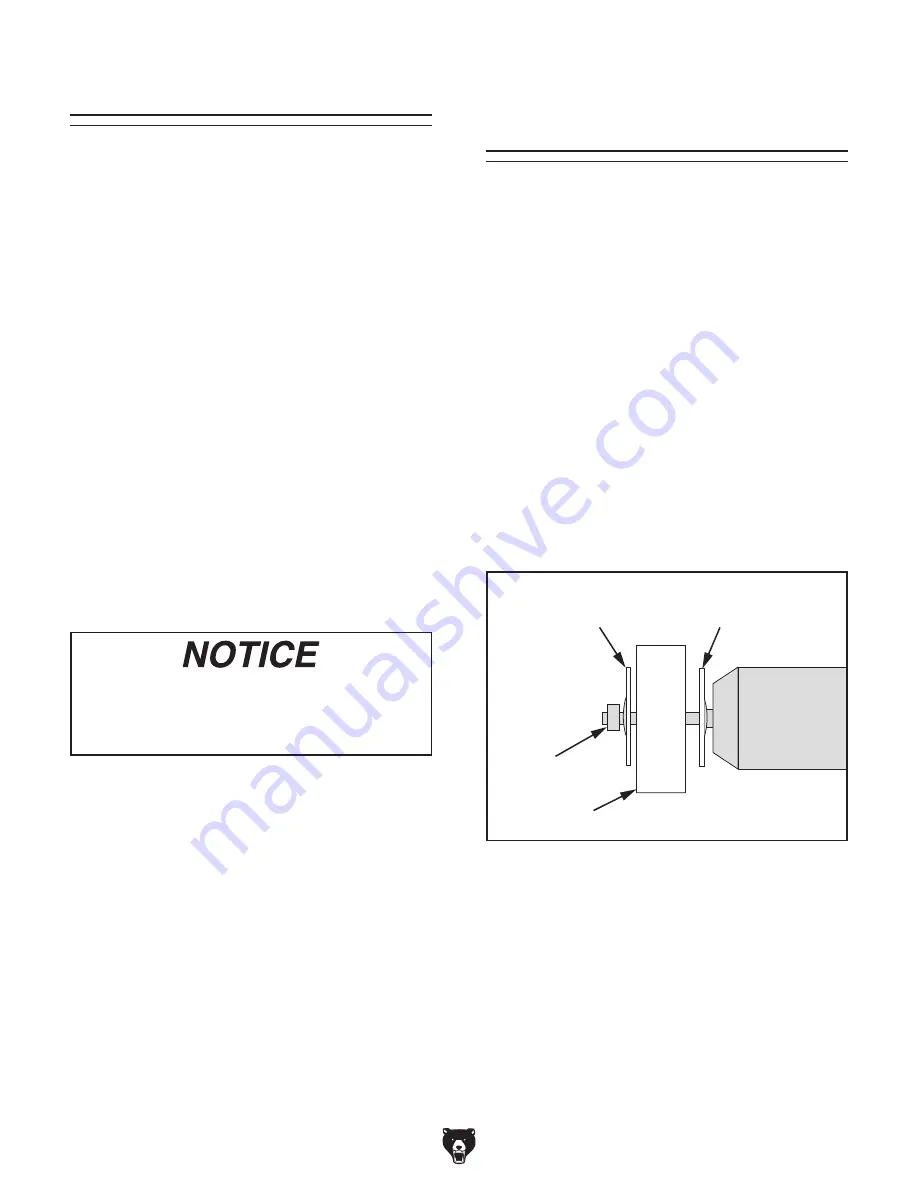

To install/remove buffing wheel:

1. DISCONNECT MACHINE FROM POWER!

This machine has a long spindle shaft that allows

for mounting many buffing accessories, depend-

ing on your application.

Installing/Removing

Buffing Wheel

Figure 15. Correct order for installing buffing

wheel components.

Hex

Nut

Wheel

Inner

Flange

Outer

Flange

2. Remove M8-1.25 hex nut (see Figure 15).

Note: Spindle shaft on left side of grinder has

left-hand threads. Turn clockwise to loosen.

3. Remove outer flange and buffing wheel from

spindle (see

Figure 15).

4. Install new buffing wheel and wheel flange

(see

Figure 15). Then re-install M8-1.25 hex

nut and tighten snugly.

Содержание T32002

Страница 36: ......