Model T32002 (Mfd. Since 02/20)

-23-

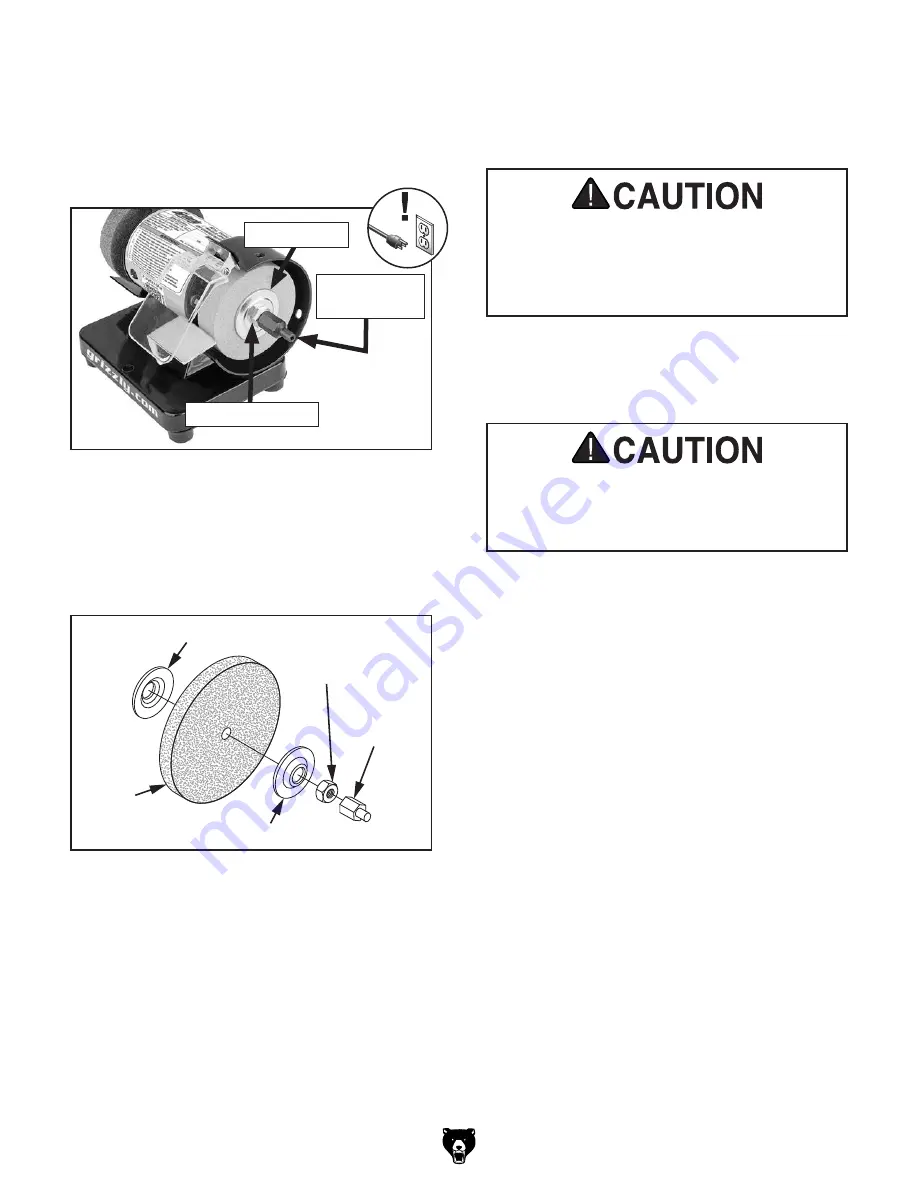

Figure 14. Assembly order for wheel installation.

Outer Flange

Inner Flange

Hex Nut

Wheel

Standoff

Stud

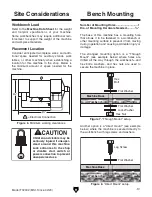

Figure 13. Outer wheel guard removed to

access grinding wheel.

Outer Flange

M8-1.25 Hex Nut

4. Remove outer wheel flange (see Figure 14).

5. Remove grinding wheel from spindle (see

Figure 14).

8. Re-assemble outer wheel guard using hard-

ware removed in

Step 2.

9. While standing to side of the machine, turn

grinder

ON and run new grinding wheel for at

least 1–2 minutes before standing in front of

it. This helps protect you if wheel has internal

damage that will cause it to fly apart from

centrifugal force of rotation.

— If grinder runs smoothly, grinding wheel

may now be used.

— If wheel appears to wobble, grinder

vibrates excessively, or any other unsafe

condition appears with new wheel, stop

grinder and refer to

Troubleshooting on

Page 29.

Warped wheel flanges can contribute to

grinding wheel breaking and flying apart.

Never use warped wheel flanges. Always

check flanges before re-installing grinding

wheel.

6. Verify the flatness of the inner and outer

flanges by placing them on a level surface. If

either flange is warped or damaged, replace

it.

3. Remove M8-1.25 standoff stud and hex nut

(see

Figure 13).

Tip: Hold grinding wheel with free hand to

stop spindle from turning while removing hex

nut.

M8-1.25

Standoff Stud

Overtightening grinding wheel can stress

and crack wheel. Cracked wheel can become

deadly projectiles when machine is turned

on.

7. Mount new grinding wheel as shown in

Figure 14. Tighten M8-1.25 hex nut and

standoff stud snugly but do not over-tighten.

Содержание T32002

Страница 36: ......