Model G0952 (Mfd. Since 09/21)

-19-

Installing/Changing

Belt

The grinding belt should be changed whenever

there is a noticeable change in grinding quality/

performance. You may also need to change grit

sizes for quick material removal or finer finishes.

Required Belt Size ................................3" x 79"

Items Needed

Qty

Belt Access Door Key........................................ 1

Replacement Belt .............................................. 1

To install/change belt:

1. DISCONNECT MACHINE FROM POWER!

2. Use key to unlock and open belt access door.

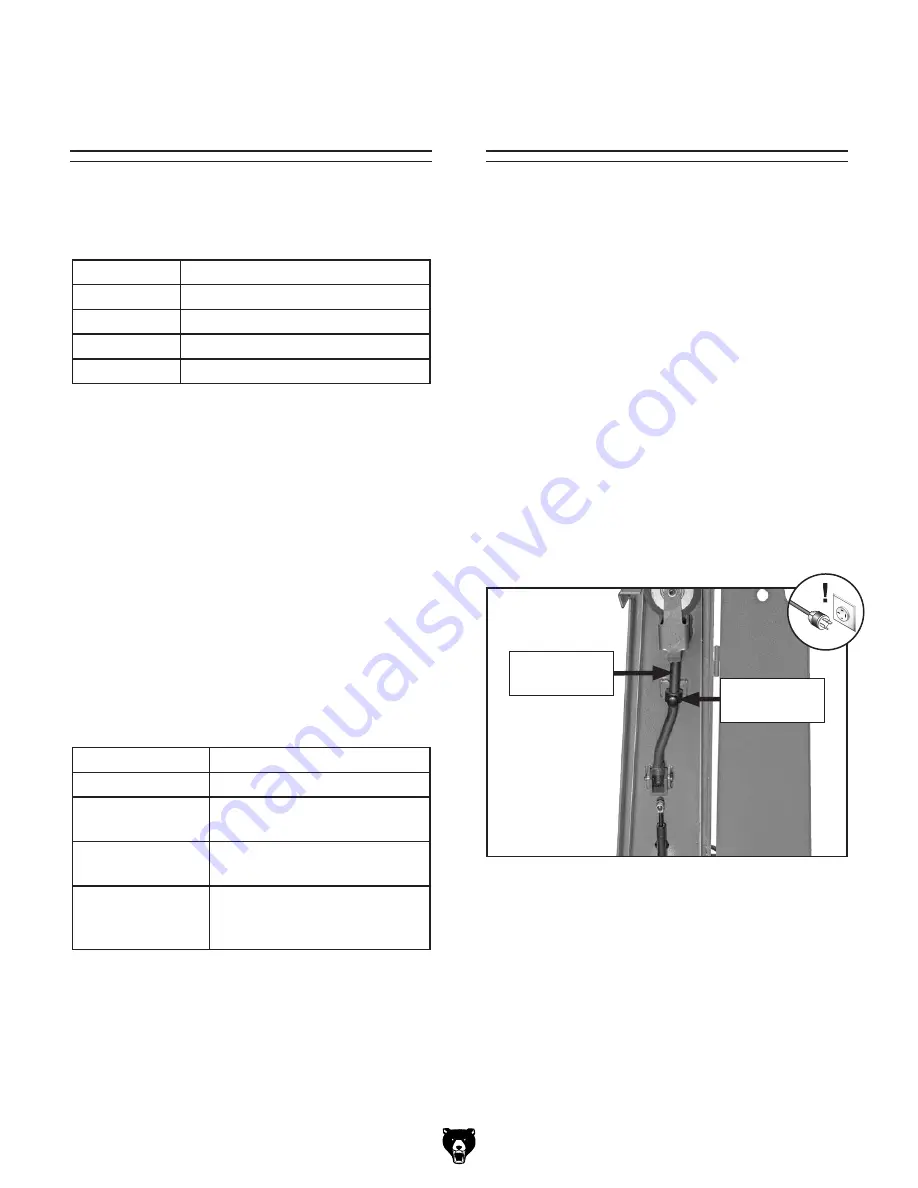

3. Turn belt tension lock knob counterclockwise

to loosen lock collar and release belt tension

lever (see

Figure 12).

Figure 12. Location of belt tension lock knob

and belt tension lever.

Belt Tension

Lever

Belt Tension

Lock Knob

This machine uses a 3" x 79" belt. Below is a

chart that groups abrasives into different classes,

and shows which grits fall into each class.

The general rule of thumb is to grind a workpiece

with progressively higher grit numbers. Avoid

skipping grits; the larger the grit increase, the

harder it will be to remove the scratches from the

previous grit.

Ultimately, the type of metal you use and your

stage of finish will determine the best grit types to

install on your grinder.

Belts are also made with different materials, and

your workpiece and intended operation will deter-

mine which belt material will produce the best

results for you. The chart below illustrates some

common belt materials and the situations that

they are most effective.

Grit

Class

36

Extra Coarse

60

Coarse

80–100

Medium

120–180

Fine

Choosing

Grinding Belts

Belt Material

Operation

Aluminum Oxide Finishing. Ferrous metals.

Zirconia Alumina Finishing; wet or dry grinding.

Ferrous metals, some steels.

Ceramic

Aggressive grinding; deburr-

ing. Heat-sensitive metals.

Silicon Carbide

Cutting; stock removal; wet

or dry grinding. Cast iron,

steel, non-ferrous metals.

Содержание G0952

Страница 36: ......