-48-

Model G0854 (Mfd. Since 08/18)

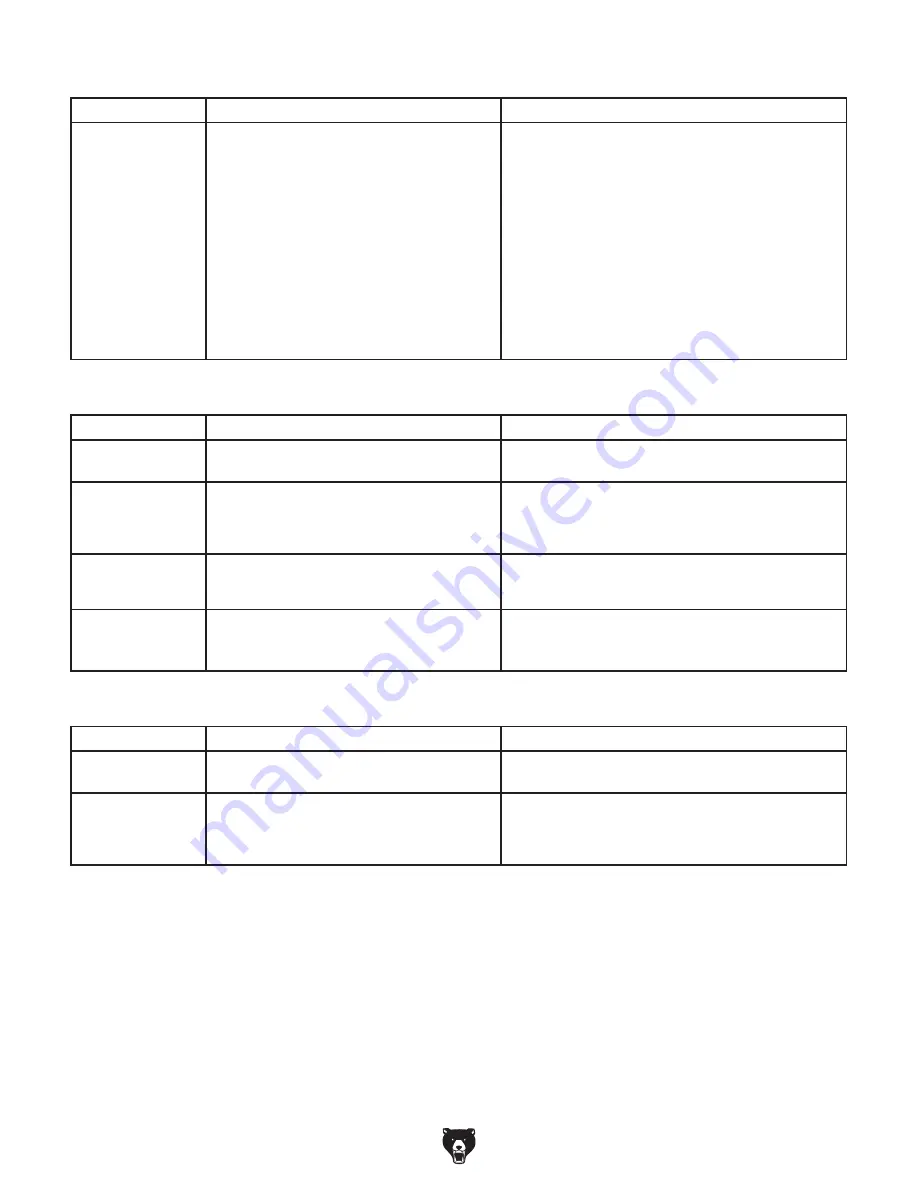

Glue Spindle (Continued)

Symptom

Possible Cause

Possible Solution

Glue only adheres

to lower portion of

workpiece edge.

1. Panel feeder not exerting enough

downward force on workpiece.

2. Panel feeder lifts up when closed and

latched.

3. Glue spindle not making full contact with

workpiece.

4. Adjustable pressure roller not making full

contact with workpiece.

5. Pressure roller tilted.

6. Glue spindle tilted.

7. Workpiece too wide, not properly

supported.

1. Lower panel feeder to 0.5mm below actual

workpiece thickness (

Page 34).

2. Adjust panel feeder latch.

3. Adjust glue spindle (

Page 36).

4. Check/adjust pressure roller (

Page 55).

5. Adjust pressure roller so it is 90° to table.

6. Adjust glue spindle so it is 90° to table.

7. Pull out table extension/use additional support, such

as roller stands.

Flush Trimmer

Symptom

Possible Cause

Possible Solution

Cutterheads do not

rotate.

1. Motor does not run.

2. Belt is loose/damaged/broken.

1. Refer to

Page 46.

2. Inspect/replace belt (

Page 56).

Flush trimmer

does not trim

proper amount of

edgebanding.

1. Cutterheads not properly adjusted.

1. Properly adjust cutterheads (

Page 37).

Cutterheads

lose RPM during

operation.

1. Belt is loose/damaged/broken.

2. Cutterhead knives are dull/broken.

1. Inspect/replace belt (

Page 56).

2. Inspect/replace knives (

Page 52).

Cutterheads will not

adjust in or out.

1. Debris stuck between cylinder and housing.

2. Burrs preventing movement.

1. Lubricate flush trimmer shafts to free up movement.

2. Remove cylinder, inspect/clean and lightly sand

both surfaces, then re-install cylinder.

Panel Feeder

Symptom

Possible Cause

Possible Solution

Conveyor belt does

not move.

1. Motor does not run.

2. Conveyor belt not properly tensioned.

1. Refer to

Page 46.

2. Properly tension conveyor belt (

Page 54).

Workpiece feeds

erratically or stops

feeding during

operation.

1. Conveyor belt not properly tensioned.

2. Panel feeder height not properly adjusted.

1. Properly tension conveyor belt (

Page 54).

2. Properly adjust panel feeder height (

Page 34).