G0803

(Mfd. Since 09/15)

-23-

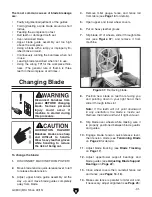

Adjusting Blade

Guide Bearings

Properly adjusting the blade guides provides side-

to-side support to help keep the blade straight

while cutting.

There are blade guide bearings on the upper and

lower blade guide assemblies. Both adjust in the

same manner. The following instructions refer to

the upper guide bearings. To access the lower

guide bearings, you must open the lower wheel

guard (see

Page 3 for reference).

Important: Make sure the blade is tracking and

tensioned correctly before performing this proce-

dure (see

Tensioning Blade on Page 20).

Tool Needed

Qty

Hex Wrench 4mm .............................................. 1

To adjust blade guides:

1. DISCONNECT MACHINE FROM POWER!

Blade

Guide

Bearing

Blade

Gullets

Approximately

0.016"

Figure 26. Blade guide bearing positioned just

behind blade gullets.

Note: With wider blades, it may not be possi-

ble to bring the guide bearings just behind the

blade gullets. Position them as far forward as

possible without allowing the guide bearing

housing to touch the back of the blade.

Blade teeth are angled out slightly, protrud-

ing wider than the blade thickness; this

is known as blade "tooth set" (see Figure

27). If teeth contact guide bearings during

operation, damage may occur. Therefore,

the support bearing must be set to prevent

teeth from contacting guide bearings during

operation (refer to Page 22 for details).

2. Loosen guide block cap screw shown in

Figure 25, then laterally position guide bear-

ings just behind blade gullets, as illustrated

in

Figure 26, then re-tighten cap screw to

secure setting.

Figure 25. Upper guide bearing components.

Guide Bearing

Adjustment

Cap Screws

Guide Bearing

(1 of 2)

Guide Block

Cap Screw

“Tooth Set”

Wider Than

Blade Thickness

BladeThickness

Figure 27. Illustration of blade "tooth set".

Содержание G0803

Страница 56: ...54 G0803 Mfd Since 09 15...

Страница 60: ......