-34-

Model G0751 (Mfg. Since 1/13)

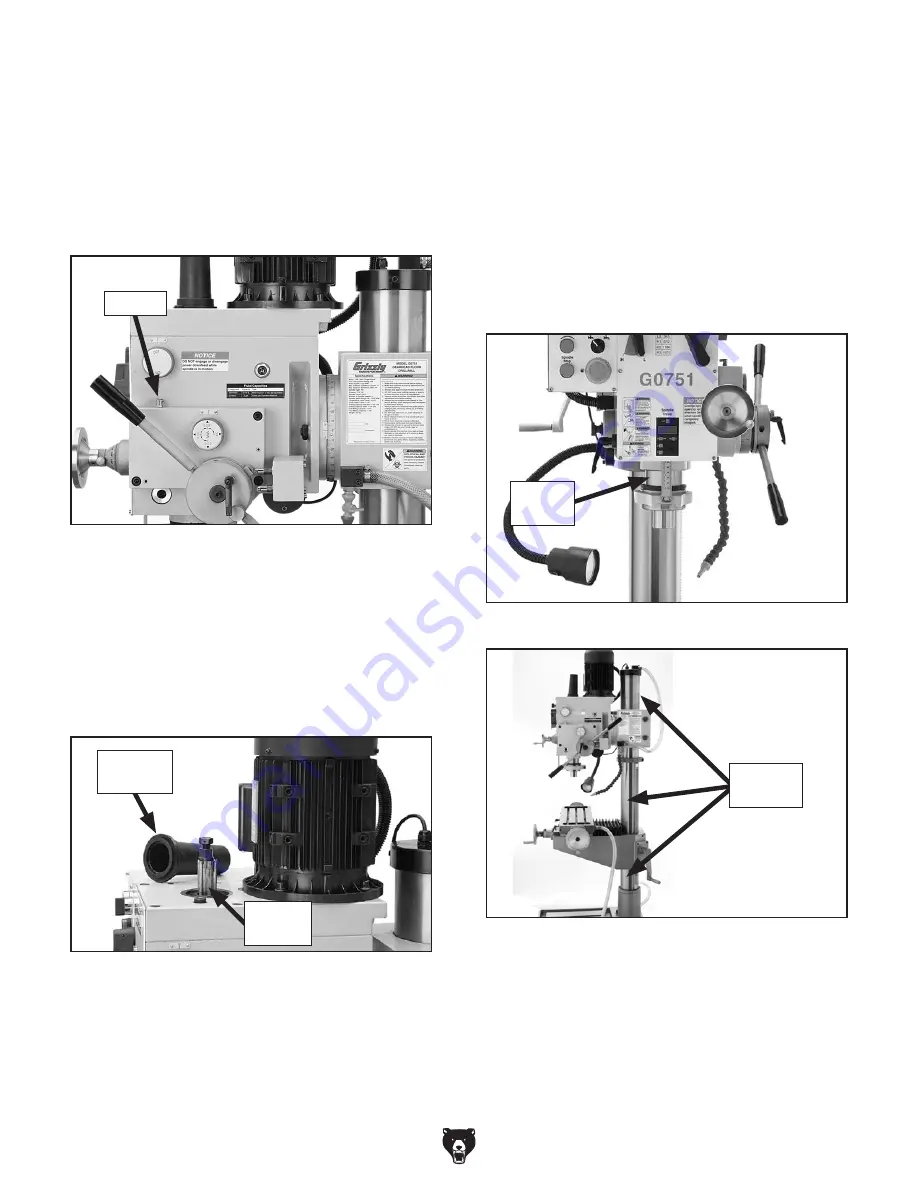

Downfeed Gears

oil type ......Model t23963 or iso 32 equivalent

oil amount ......................................... Fill oil Cup

Lubrication Frequency ...........8 hrs. of operation

Lift the oil cup cap (see

Figure 37) to fill the cup

with oil. the oil will slowly drain into the downfeed

gears over time.

Spindle Spline

grease type ......... nLgi#2 grease or equivalent

grease amount .............................small amount

Lubrication Frequency ....................... Bi-annually

remove the drawbar cap (see

Figure 38) to

expose the spindle spline.

Quill & Column Surfaces

oil type ......Model t23962 or iso 68 equivalent

oil amount ............................................thin Coat

Lubrication Frequency ...........8 hrs. of operation

Use the controls to access the entire smooth

surfaces of the quill and column (see

Figures

39– 40), then clean them with mineral spirits and

shop rags.

Note: Avoid removing the grease from the column

racks during cleaning.

When dry, apply a thin coat of oil to the surfaces.

Move the components through the entire path of

travel to distribute the lubricant.

Figure 40. Column surface locations.

Column

surfaces

Figure 39. Quill surface location.

Quill

surface

Figure 37. downfeed gears oil cup location.

oil Cup

Figure 38. spindle spline location.

drawbar

Cap

spindle

spline

Use the coarse downfeed handles to lower the

spindle, then apply a small amount of grease

inside the resulting hole. run the spindle up and

down several times to distribute the grease.

Содержание G0751

Страница 64: ......