Model G0746/G0749 (Mfg. Since 3/13)

-83-

as the brake lining wears, the foot pedal develops

more travel. if the brake band is not adjusted to

compensate for normal wear, the limit switch will

still turn the lathe

OFF, but the spindle will not

stop as quickly. it is especially important that the

brake is kept properly adjusted so you can quickly

stop the spindle in an emergency.

Tools Needed:

Qty

Wrench 17mm.................................................... 1

hex Wrench 8mm .............................................. 1

Adjusting brake

1. disCoNNECt lathE FroM poWEr!

2. put on a respirator and eye protection to pro-

tect yourself from hazardous brake dust.

3. open the end-gear cover.

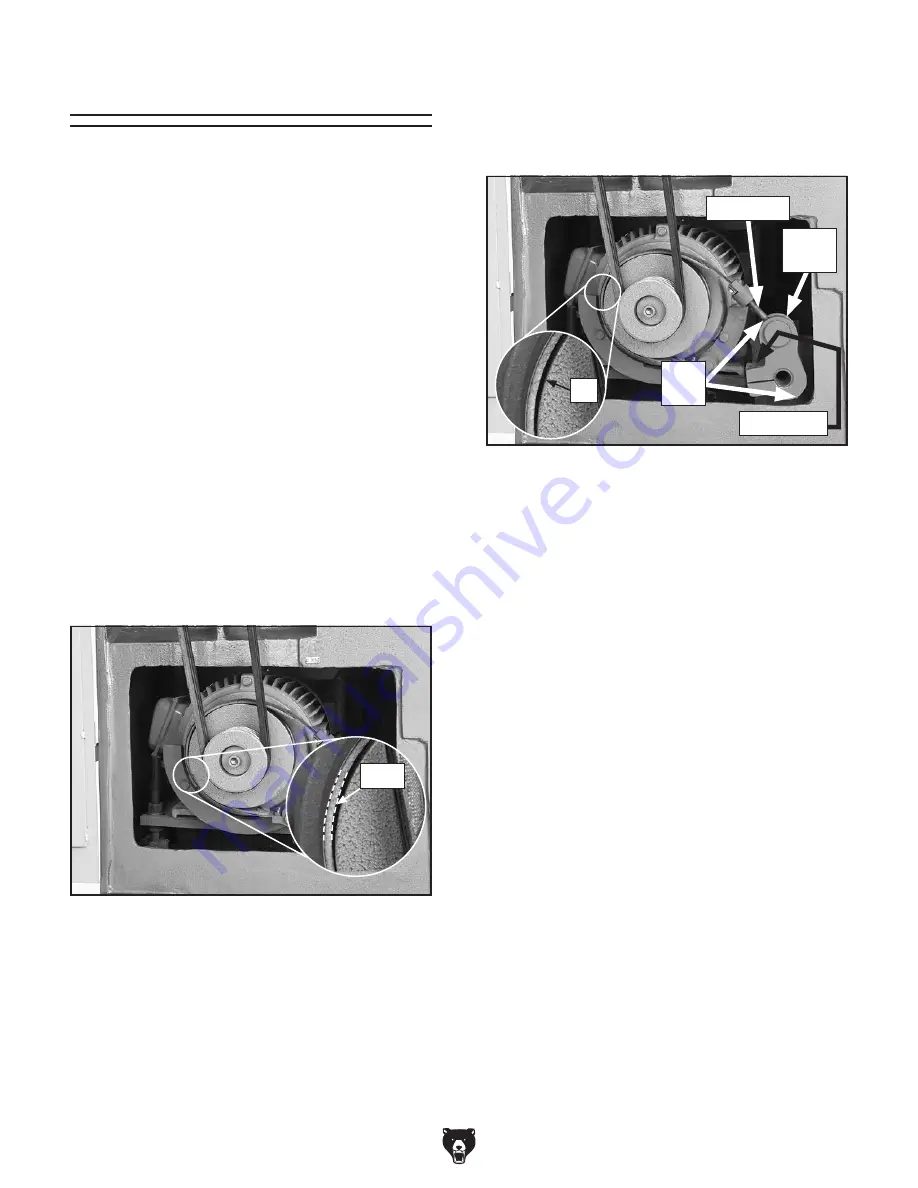

4. Measure the remaining brake band lining

at the thinnest point, which is usually at the

8 o'clock position, as shown in

figure 136.

brake & Switch

Note: When the brake band is new, the lining

is approximately 4mm thick. If the lining thick-

ness wears to 1m or less, the brake band

must be replaced.

figure 136. Minimum brake belt thickness.

1mm

5. adjust the hex nuts on the pedal bolt shown

in

figure 137 to tighten the brake band so

there is approximately

1

⁄

8

" clearance between

the pad and hub around its circumference.

figure 137. Brake tensioning components.

pedal Bolt

hex

Nuts

pedal

lever

—if additional brake band tension is needed,

loosen the cap screw shown in

figure 137,

pivot the pedal lever to the right and tighten

the cap screw.

6. Close the end-gear cover, connect the lathe

to power, then test the brake pedal as follows:

a. start the lathe, then lightly press the foot

pedal. the motor should shut

OFF.

b. push the foot pedal down further to stop

spindle rotation. you should not need to

press the pedal down completely to stop

the spindle, nor should the spindle keep

rotating. if either symptom occurs, repeat

Steps 5–6 until you are satisfied with the

brake performance.

Cap screw

1

⁄

8

"