Model G0746/G0749 (Mfg. Since 3/13)

-45-

Note:

The maximum quill travel is 4

3

⁄

4

", but

we do not recommend extending the quill

more than 2" or stability and accuracy will be

reduced.

Removing center from Tailstock

Mounting Workpiece between

centers

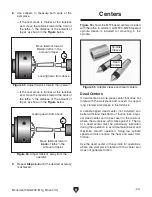

figure 58. Example photo of a workpiece

mounted between the centers.

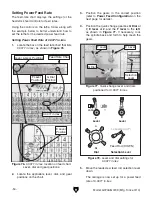

3. Use the quill handwheel to feed the quill out

from the casting approximately 1”.

4. insert the center into the tailstock quill.

5. seat the center firmly into the quill during

workpiece installation by rotating the quill

handwheel clockwise to apply pressure with

the center engaged in the center hole in the

workpiece.

Note:

Only apply enough pressure with the

tailstock quill to securely mount the work-

piece between centers. Avoid overtightening

the center against the workpiece, or it may

become difficult to remove later, and it will

result in excessive friction and heat, which

may damage the workpiece and center.

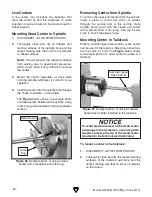

to remove the center from the quill, hold onto it

with a gloved hand or shop rag, then rotate the

quill handwheel counterclockwise to draw the quill

back into the casting until the center releases.

if the center does not come loose by retracting the

quill, extend the quill to expose the slot shown in

the

figure below, then use a drift key to remove

the center.

1. disCoNNECt lathE FroM poWEr!

2. drill center holes in both ends of the work-

piece.

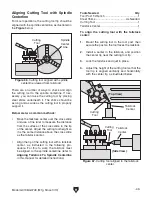

3. install a dead center in the spindle with a

lathe dog and a chuck, faceplate or drive

plate, then install a live center or carbide-

tipped dead center in the tailstock.

4. lubricate the workpiece center holes, then

mount it between the centers and hold it in

place with light pressure from the tailstock

center.

5. seat the center firmly into the quill by rotating

the quill handwheel clockwise to apply pres-

sure against the workpiece (see example in

figure below).

Note: Only apply enough pressure to securely

mount the workpiece between centers. Avoid

over-tightening the center against the workpiece,

or it may become difficult to remove later. Also,

over-tightening will result in excessive friction and

heat, which may damage the workpiece or center.