Model G0746/G0749 (Mfg. Since 3/13)

-29-

2. read and follow the safety instructions at the

beginning of the manual, take all required

safety precautions, and make sure all pre-

vious preparation steps discussed in this

manual have been followed and completed.

3. Clear away all tools and objects used during

assembly, lubrication, and preparation.

4. Make sure that the chuck and jaws, if installed,

are secure

.

Note: If a chuck is not installed on the lathe,

you do not need to install one for this test.

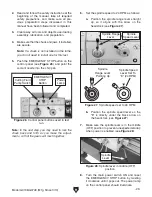

5. push the EMErgENCy stop button on the

control panel (see

figure 26), and point the

coolant nozzle into the chip pan.

Note: In the next step, you may need to rock the

chuck back and forth as you make the adjust-

ments, so that the gears will mesh together.

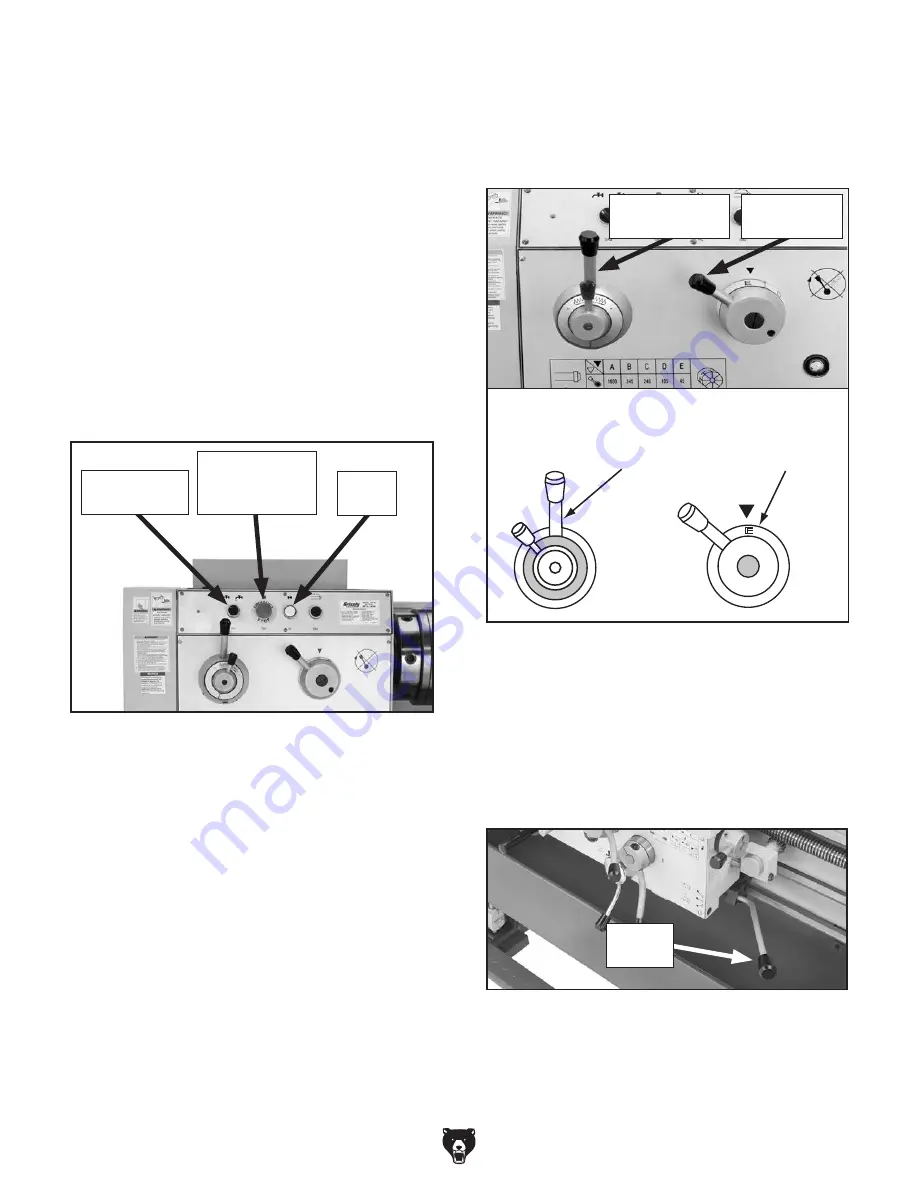

figure 26. Control panel buttons used in test

run.

power

lamp

Cutting Fluid

pump switch

EMErgENCy

stop

Button

6. set the spindle speed to 24 rpM as follows:

a. position the spindle range lever straight

up, so it aligns with the arrow on the

headstock (see

figure 27).

b. position the spindle speed lever so the

"E" is directly under the black arrow on

the headstock (see

figure 27).

7. Make sure the spindle lever is in the middle

(oFF) position to prevent unexpected startup

when power is enabled (see

figure 28).

Spindle Speed

Lever Set To

“E” (24 RPM)

Spindle

Range Lever

Pointing Up

E

figure 27. spindle speed set to 24 rpM.

spindle

speed lever

spindle range

lever

figure 28. spindle lever in middle (oFF)

position.

spindle

lever

8. turn the main power switch oN and reset

the EMErgENCy stop button by twisting

it clockwise until it pops out. the power lamp

on the control panel should illuminate.