-58-

Model G0746/G0749 (Mfg. Since 3/13)

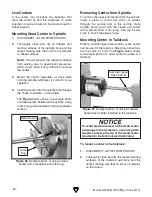

Apron Threading controls

the half nut lever engages the carriage with the

leadscrew, which moves the carriage and cutting

tool along the length of the workpiece for thread-

ing operations (see

figure 88).

important: Make sure the feed lever and feed

selection lever are in the disengaged position

before attempting to engage the half nut.

figure 88. apron threading controls.

Feed

selection

lever

Feed

lever

half Nut

lever

Cross Slide

Disengaged

Feed Selection

Lever

Feed

Lever

Carriage

Engaged

Engaged

Half Nut

Lever

Disengaged

Disengaged

Thread Dial

Tools Needed

Qty

open-End Wrench 14mm .................................. 1

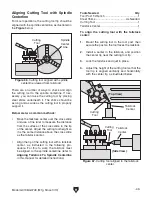

the numbers on the thread dial are used with

the thread dial chart to show when to engage the

half nut during inch threading. loosen the hex nut

on the thread dial (see

figure 89), pivot the gear

teeth so they mesh with the leadscrew threads,

then re-tighten the hex nut.

Note: The thread dial is not used for metric

threading or pitch turning. You must leave the half

nut engaged from the beginning until the turning

is complete for this type of operation.

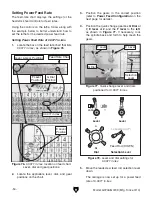

When threading, we recommend using the

slowest speed possible and avoiding deep

cuts, so you are able to disengage the half

nut when required and prevent an apron

crash!

When the first thread cutting pass is complete,

the operator disengages the carriage from the

leadscrew using the half nut lever. the operator

returns the carriage for the next pass and re-

engages the half nut using the same thread dial

setting to resume the cut in the previous pass.

figure 89. thread dial engaged with the

leadscrew.

dial gear

teeth

leadscrew

hex Nut