-20-

Model G0734/G0735 (Mfd. Since 12/15)

Air Nozzle

The air nozzle blows air at the blade to keep wood

debris away from the line of the cut. This makes it

easier to follow your cutting lines with accuracy.

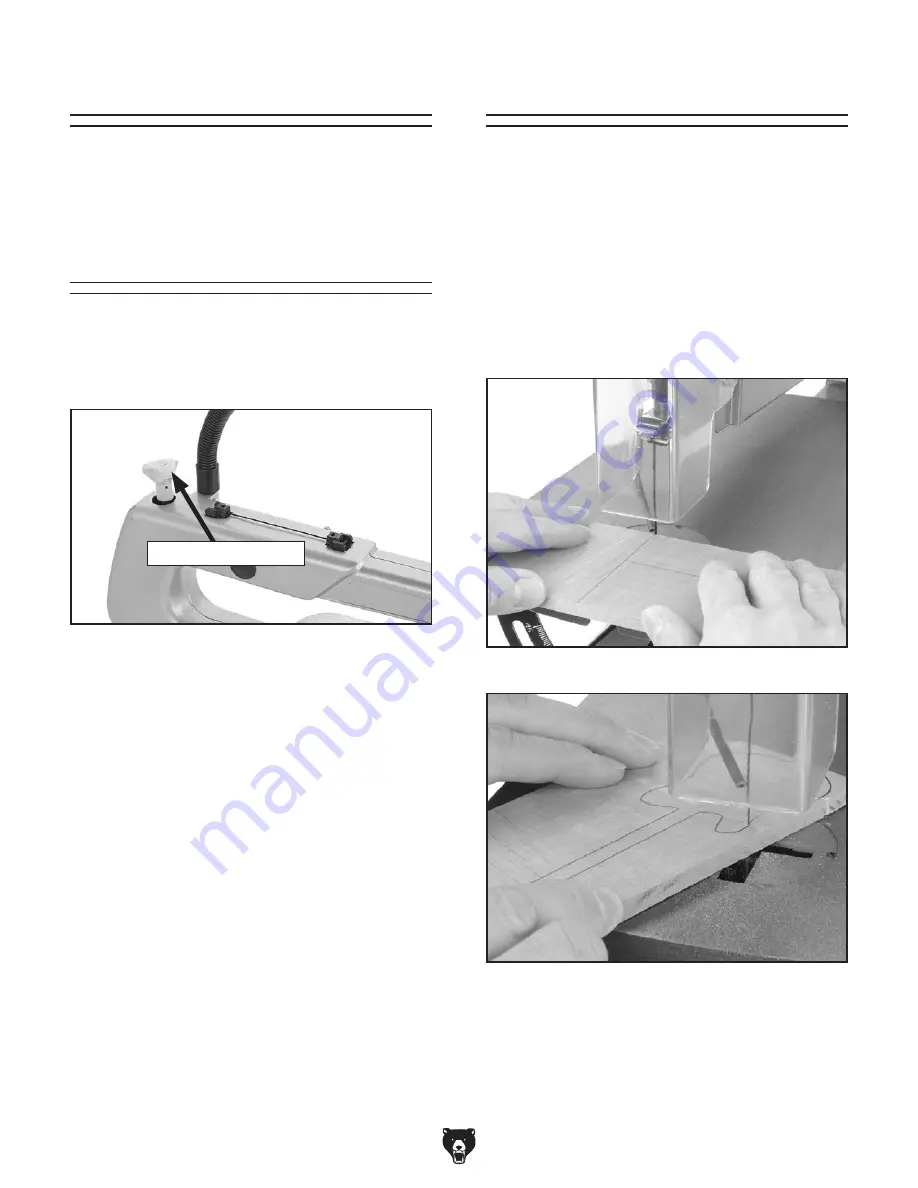

Standard Scroll Cuts

For standard scroll cutting, follow the pattern

line on the workpiece by pushing and turning the

workpiece at the same time, which allows the kerf

of the cut to make way for the turn.

DO NOT turn the workpiece without pushing it

through the blade at the same time; otherwise, the

blade could twist and break.

See

Figures 21–22 for examples of standard

scroll cutting.

Figure 21. Example of a straight cut.

Figure 22. Example of making a curved cut.

Blade Tension

Blade tension is adjusted using the knob shown in

Figure 20. Turn the blade tension knob clockwise

to increase the blade tension and counterclock-

wise to decrease it.

Figure 20. Blade tension knob.

Blade Tension Knob

If the blade is not tensioned enough, it will drift

while cutting, making it difficult to follow your cut-

ting lines. If the blade is too tight, it can break or

cause damage to the saw.

To check/adjust the blade tension:

1. DISCONNECT POWER TO SAW!

2. Pivot the blade guard up.

3. Pinch the blade and move it side to side with

light pressure to check the tension. When

properly tensioned, the blade will deflect only

slightly when moved and the ends will remain

firmly in position.

4. Tighten/loosen the blade as necessary and

pivot the blade guard down. Perform a test

cut on a scrap piece of wood and repeat this

entire procedure if further adjustments are

necessary.

Содержание G0734

Страница 40: ......