Model G0654 (Mfg. Since 9/07)

-35-

Gibs: lower the infeed and outfeed table to

access the gibs. annually place a couple drops of

oil at the top of each gib and move the tables up

and down to distribute the oil. see the locations

shown in

figure 61 and parts 73 and 74 on page

46. Wipe off excess oil.

figure 61. location to lubricate gibs.

v-Belt

v-belt removal and replacement involves remov-

ing the v-belt, rolling it off of the pulleys, replacing

it with a new belt, then tensioning it.

Consider replacing the stock belt with a power

twist v-belt (see

page 32) to reduce vibration

and noise, and increase belt lifespan.

To adjust/replace the v-belt:

1. disConneCt Jointer From poWer!

Note: DO NOT completely remove the motor

mount hex nuts.

figure 63. motor mount hex nuts.

4. remove the v-belt and replace it with a new

one.

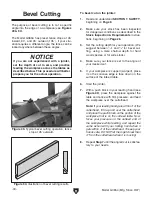

5. lower the motor and adjust the v-belt ten-

sion as needed so there is approximately

1

⁄

4

"

deflection when the v-belt is pushed with

moderate pressure, as shown in

figure 64.

Note: After the first 16 hours of belt life, ten-

sion the belt, as it will stretch and seat during

this time.

figure 64. Checking v-belt tension.

Pulley

Deflection

Pulley

1

⁄

4

"

6. tighten the motor mount bolts, replace the

rear access panel and belt guard.

fence: place one or two drops of light machine oil

on the fence pivot points (

figure 62) as needed.

figure 62. Fence lubrication locations.

2. remove the rear access panel and belt

guard.

3. using a 12mm wrench, loosen the motor

mount bolts shown in

figure 63, raise the

motor to remove the v-belt tension.

gib lubrication locations

Fence lubrication locations

hex nuts

Содержание G0654

Страница 56: ......