-38-

Model G0495X (Mfd. Since 07/19)

IMPORTANT: The steps below are intended to be

performed in succession with the steps involved

in checking the outfeed table. Do not continue

until you have followed those steps.

To adjust the table parallelism:

1. Place the straightedge on the outfeed table

so it hangs over the cutterhead, then lower

the outfeed table until the straightedge just

touches the cutterhead body, as shown in

Figure 34 (rotate the cutterhead if necessary).

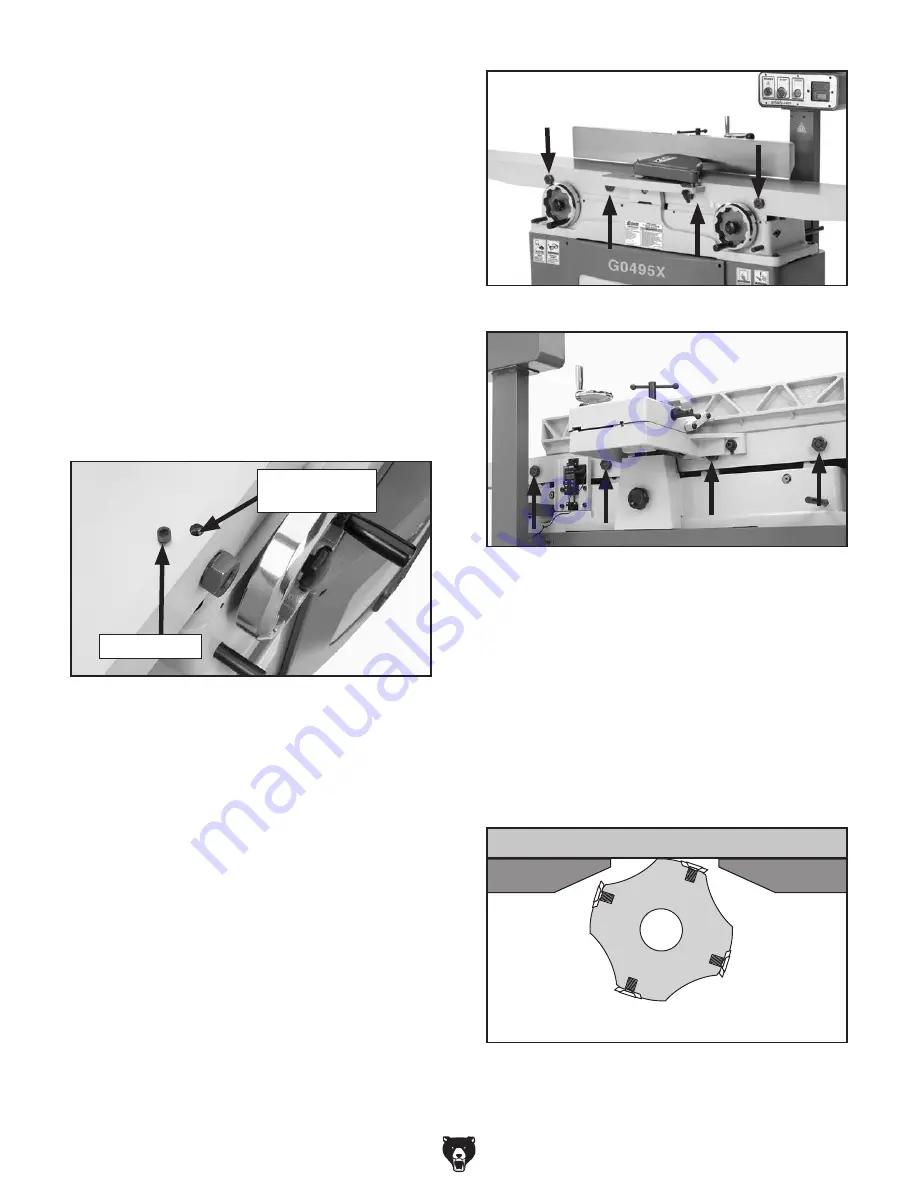

2. Remove the screw cover (see Figure 39)

covering each set screw on the outfeed table.

Note: It may help to clean the screw covers

with electrical parts cleaner. Push duct tape

firmly against the cover, then pull straight up.

Figure 40. Front eccentric bushings.

3. Loosen each set screw (see Figure 39) two

turns.

4. Place the straightedge in one of the positions

shown in

Figure 35, and adjust the table by

turning the eccentric bushings (

Figures 40 &

41) as needed with an adjustable wrench so

that the straightedge touches the cutterhead

while lying flat across the outfeed table.

Repeat this step with each of the remaining

straightedge positions as many times as nec-

essary until the outfeed table is parallel with

the cutterhead to within 0.010"-0.012".

Note: Setting the outfeed table parallel to the

cutterhead within 0.010"-0.012" will produce

high quality results. Going lower than this

number will produce minimal gain.

5. Tighten the set screws and replace the screw

covers on the outfeed table.

6. Remove each of the four screw covers on

the infeed table, and loosen the set screws

underneath.

7. Place the straightedge halfway across the

infeed table and halfway over the outfeed

table, then adjust the infeed table even with

the outfeed table, as shown in

Figure 37.

Straightedge

Outfeed Table

Infeed Table

Figure 42. Infeed and outfeed tables adjusted

even.

Figure 41. Rear eccentric bushings.

Figure 39. Screw cover and set screw location.

Screw Cover

Set Screw

(Out of View)