Indirect Gas-Fired Heat Modules

19

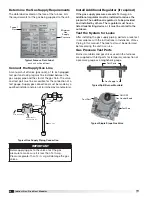

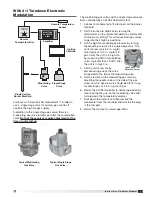

The modulating gas valve and the single stage valve are

both controlled by an A1092 Control System.

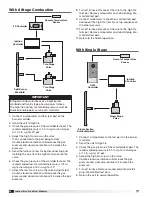

1. Connect a manometer to the test port on the burner

manifold.

2. Set the furnace to High Fire by turning the

temperature on the remote temperature selector dial

to maximum setting. This will cause both gas valves

to go into their high fire positions.

3. Set the high fire manifold gas pressure by turning

the adjusting screw on the single stage valve. The

correct pressure is 3.5 in. wg for

natural gas or 10.0 in. wg for LP

gas. Verify the unit is in high fire

by measuring VDC at modulating

valve. If greater than 15 VDC, then

the unit is in high fire.

4. Set the unit to low fire by

disconnecting one of the wires

connected to the top of the modulating valve.

5. Set the low fire on the modulating gas valve by

adjusting the needle valve on the side of the gas

valve. Low fire gas pressure should be 0.875 in. wg

for natural gas or 2.5 in. wg for LP gas.

6. Return the A1092 Controller to normal operation by

reconnecting the wire on the modulating valve and

turning down the temperature selector.

7. Shut down the furnace and then remove the

manometer from the manifold and reinstall the plug

in the test port.

8. Return the furnace to normal operation.

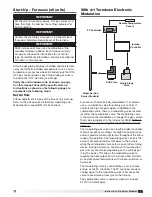

Furnaces with electronically modulated 2:1 turndown

use a single stage valve for primary gas control. It

controls the high fire gas supply.

In addition to the single stage gas valve, there is a

modulating gas valve located just after the combination

valve.

Both of these valves require adjustment at the

time of unit start-up

.

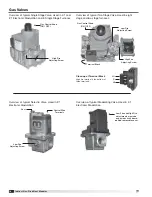

High Fire

Adjusting Screw

With 2:1 Turndown Electronic

Modulation

Typical Modulating

Gas Valve

Typical Single Stage

Gas Valve

Modulating

Valve

Single Stage

Valve

Single Section

Burner Manifold

Remote Temperature

Sensor

Remote

Temperature Dial

Amplifier

MAXITROL

SELECTRA

MAXITROL

SELECTRA

A1092

50

70

80

90

60

MAXITROL

SELECTRA

Ignition

Controller

®