Indirect Gas-Fired Heat Modules

17

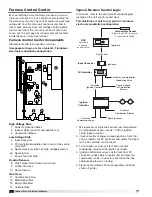

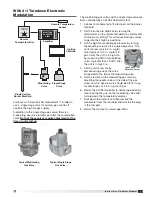

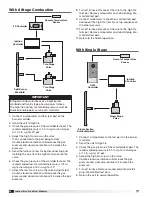

Furnaces with electronically modulated 4:1 turndown

use a combination valve for primary gas control. It

controls the high fire gas supply. In addition to the

combination valve, there is a modulating valve located

just after the combination valve. The modulating valve

is the device that modulates or changes the gas volume

that is being supplied to the furnace manifold.

Both of

these valves require adjustment at the time of unit

start-up.

The modulating gas valve has a built-in digital controller

that will accept user settings for High Fire and Low Fire

and will provide minimal hysteresis throughout the entire

range of modulation. The modulating valve controls the

amount of combustion gas that goes to the burners,

while the combination valve acts as an on/off switching

device. During normal use, the amount of combustion

gas will vary constantly, depending on the settings put

in by the owner. This allows the modulating valve to

regulate the heat output from the furnace and maintain

a constant space temperature with minimal variation, or

hysteresis.

The modulating valve is controlled by a user interface

known as the FX controller. The FX controller sends an

analog signal to the modulating valve that causes the

valve to send more or less gas to the furnace.

The combination valve is normally closed. It requires

24 VAC to hold it open.

With 4:1 Turndown Electronic

Modulation

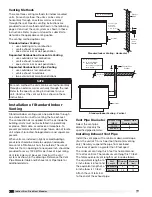

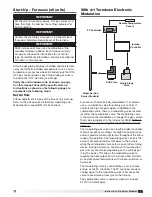

Start-Up - Furnaces (all units)

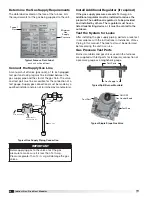

After the gas piping has been installed and leak tested,

verify that all field-installed components such as an air

temperature sensor have been installed. Verify that ON/

OFF gas control knob on each stage-type gas valve is

turned to the “ON” position (see image).

Verify the unit turndown ratio as shown on page

2 of this manual. Consult the specific start-up

instructions as shown on the following pages to

accomplish the following steps:

Set Airflow

Airflow adjustment is done at the time of unit start-up.

Refer to the unit-specific Installation, Operating and

Maintenance manual (IOM) for instructions.

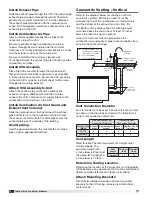

IMPORTANT

For the unit to function properly, ALL gas valves must

have their high fire and low fire settings adjusted for

field conditions.

IMPORTANT

Confirm the discharge air sensor is installed at least

three duct diameters downstream of the furnace.

IMPORTANT

Multi-furnace units may use a combination of the

available turndown options. Each furnace must be

set-up per the specific instructions for its control

type. For additional information, see

Gas-Fired Burner

Turndown

in this manual.

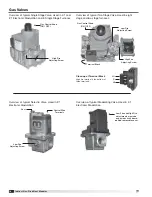

EXA Valve

Single Stage

Valve

Single Section

Burner Manifold

Remote Temperature

Sensor

Ignition

Controller

FX Controller

®