1. Use scissors or a sharp hobby knife to cut the decals from

the sheet.

2. Be certain the model is clean and free from oily

fingerprints and dust. Prepare a dishpan or small bucket with

a mixture of liquid dish soap and warm water–about one

teaspoon of soap per gallon of water. Submerse the decal in

the soap and water and peel off the paper backing. Note:

Even though the decals have a “sticky-back” and are not the

water transfer type, submersing them in soap & water allows

accurate positioning and reduces air bubbles underneath.

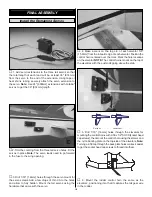

3. Position decal on the model where desired. Holding the

decal down, use a paper towel to wipe most of the water away.

4. Use a piece of soft balsa or something similar to

squeegee remaining water from under the decal. Apply the

rest of the decals the same way.

❏

1. Turn on the transmitter and receiver and center the

trims. If necessary, remove the servo arms from the servos

and reposition them so they are centered. Reinstall the

screws that hold on the servo arms.

❏

2. With the transmitter and receiver still on, check all the

control surfaces to see if they are centered. If necessary, adjust

the clevises on the pushrods to center the control surfaces.

❏

3. Make certain that the control surfaces and the

carburetor respond in the correct direction as shown in the

diagram. If any of the controls respond in the wrong direction,

use the servo reversing in the transmitter to reverse the

servos connected to those controls. Be certain the control

surfaces have remained centered. Adjust if necessary.

Use a ruler or Great Planes Accu-Throw

™

Deflection Gauge

(GPMR2405) to accurately measure and set the control throw of

each control surface as indicated in the chart that follows. If your

radio does not have dual rates, we recommend setting the

throws at the low rate settings. NOTE: The throws are measured

at the widest part of the elevators, rudder and ailerons.

At this stage the model should be in ready-to-fly condition

with all of the systems in place including the engine, landing

gear, covering and the radio system.

❏

1. Use a felt-tip pen or 1/8"-wide tape to accurately mark

the C.G. on the top of the wing. The C.G. is located 4-3/4"

[120mm] back from the leading edge of the wing.

This is where your model should balance for your first

flights. Later, you may wish to experiment by shifting the

C.G. up to 3/4" [20mm] forward or 3/4" [20mm] back to

change the flying characteristics. Moving the C.G. forward

may improve the smoothness and stability, but it may then

require more speed for takeoff and make it more difficult

to slow for landing. Moving the C.G. aft makes the model

more maneuverable, but could also cause it to become

too difficult for you to control. In any case, start at the

location we recommend and do not at any time balance

your model outside the recommended range.

More than any other factor, the C.G. (balance point) can

have the greatest effect on how a model flies and may

determine whether or not your first flight will be successful.

If you value this model and wish to enjoy it for many flights,

DO NOT OVERLOOK THIS IMPORTANT PROCEDURE.

A model that is not properly balanced will be unstable and

possibly unflyable.

Balance the Model (C.G.)

We recommend the following control surface throws:

High Rate (3D)

Low Rate

ELEVATOR:

2-1/4" [57mm] up

1" [25.5mm] up

2-1/4" [57mm] down

1" [25.5mm] down

RUDDER:

3-1/2" [89mm] right

1-1/2" [38mm] right

3-1/2" [89mm] left

1-1/2" [38mm] left

AILERONS:

2-1/2" [63.5mm] up

1-1/4" [32mm] up

2-1/2" [63.5mm] down 1-1/4" [32mm] down

Set the Control Throws

CARBURETOR WIDE OPEN

RUDDER MOVES RIGHT

LEFT AILERON MOVES DOWN

RIGHT AILERON MOVES UP

ELEVATOR MOVES UP

4-CHANNEL

TRANSMITTER

(STANDARD MODE 2)

4-CHANNEL RADIO SETUP

TRANSMITTER

4-CHANNEL

TRANSMITTER

4-CHANNEL

TRANSMITTER

4-CHANNEL

Check the Control Directions

GET THE MODEL READY TO FLY

Apply the Decals

21