26

After testing this plane with several different engines, props,

CG locations and countless different control throw settings,

I found the following setup to be ideal for my particular style

of flying 3D.

Mike Cross, Two Time US National Freestyle IMAC Champion

4-3/4" back from the LE of the wing. This is the normal

recommended CG and is perfect for the aircraft to hover.

Going forward or aft creates a small amount of coupling

between the rudder and elevators while hovering. This CG is

also very responsive but still has a comfortable “feel” in flight.

After extensive flight testing, the following engines are

recommended:

O.S. FS-70 II (OSMG0872), 14x6 APC (APCQ1406), Wildcat

15% nitro (CATP1105).

The .46FX hovers pretty well but is a little lacking when

things get out of shape.

The .50SX (OSMG0550) hovers almost as well as the

FS-70 with the same 14x6 APC prop. It is not quite as

steady as the FS-70.

NOTE: Flying on the OS .91FS caused more tail weight to

be needed, made it so the plane would not sit still on the

runway and made it difficult to maintain a hover. The

hovering was hindered by using such a low throttle setting

that the poor throttle resolution made it very difficult to stay

in one spot. We do not recommend a .91 4-stroke or larger

engine. Using a larger engine than recommended will put

your model at high risk for catastrophic failure and void any

protections offered in its warranty.

Spinner 2" True Turn (TRUQ1060) and True Turn lock nut

(TRUQ3063) for the FS-70, or lock nut (TRUQ3040) for the

.50 SX.

Note: A 2" nylon spinner is included with the U-Can-Do 3D

but with the larger engines it requires extensive trimming of

the spinner. If you have to extensively trim the spinner, we

strongly suggest using an aluminum spinner instead.

Elevators:

Futaba 9250 digital (FUTM0220)

Ailerons:

Futaba 9250 digital

Rudder:

Futaba 9151 digital (FUTM0211)

Throttle:

Futaba 9001 (FUTM0075)

The large control throws require a servo with great centering.

The digital servos are second to none in this department. You

can NOT expect this aircraft to give you optimum performance

on non-ball-bearing standard servos such as Futaba S148.

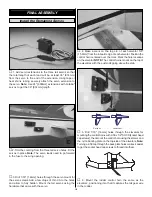

Larger than stock servo arms are highly recommended for

getting the 3D throws from the U-Can-Do 3D. Do not move

the pushrods in on the control horns to get the increased

throw, as doing this intensifies any play in the system.

Dubro Super Strength Arms set (DUBM6670):

• The longest single sided arm was used on the rudder.

• The mid sized single sided arms were used on the elevators.

• The double-sided arms were made into single sided

aileron servo arms.

GOOD LUCK AND GREAT FLYING!

Servo Arms

Servos

Spinner

Engine

C.G.

PERFORMANCE SETTINGS

FOR THE U-CAN-DO 3D .46 ARF