If you are building the 20 or 40 Sports Floats, skip to

“Construction of 20, 40, 60 Floats” in the next column

on this page.

❏

1. On a flat surface covered with wax paper, laminate the

die-cut 1/8" plywood forward and aft spine to one 1/16" die-

cut plywood spine doubler with 6-minute epoxy. Use weights

to hold the pieces together. Hint: Before the epoxy fully

cures, use a #11 blade to remove excess epoxy that gets into

the notches or oozes out from between the laminated pieces.

With Great Planes 6-minute Pro

™

Epoxy, this can be done

about 10 to 15 minutes after the epoxy has been mixed.

❏

2. Glue the other doubler to the other side of the

assembly with 6-minute epoxy.

❏

1. Since the par ts are smaller, both forward keel

doublers may be laminated to the forward keel at the same

time. Mix up some 6-minute epoxy and apply to one side of

both die-cut 1/16" plywood forward keel doublers. Then

position a doubler on each side of the die-cut 1/8" plywood

forward keel. Hold the pieces together with weights.

Remove the excess epoxy before it fully cures.

❏

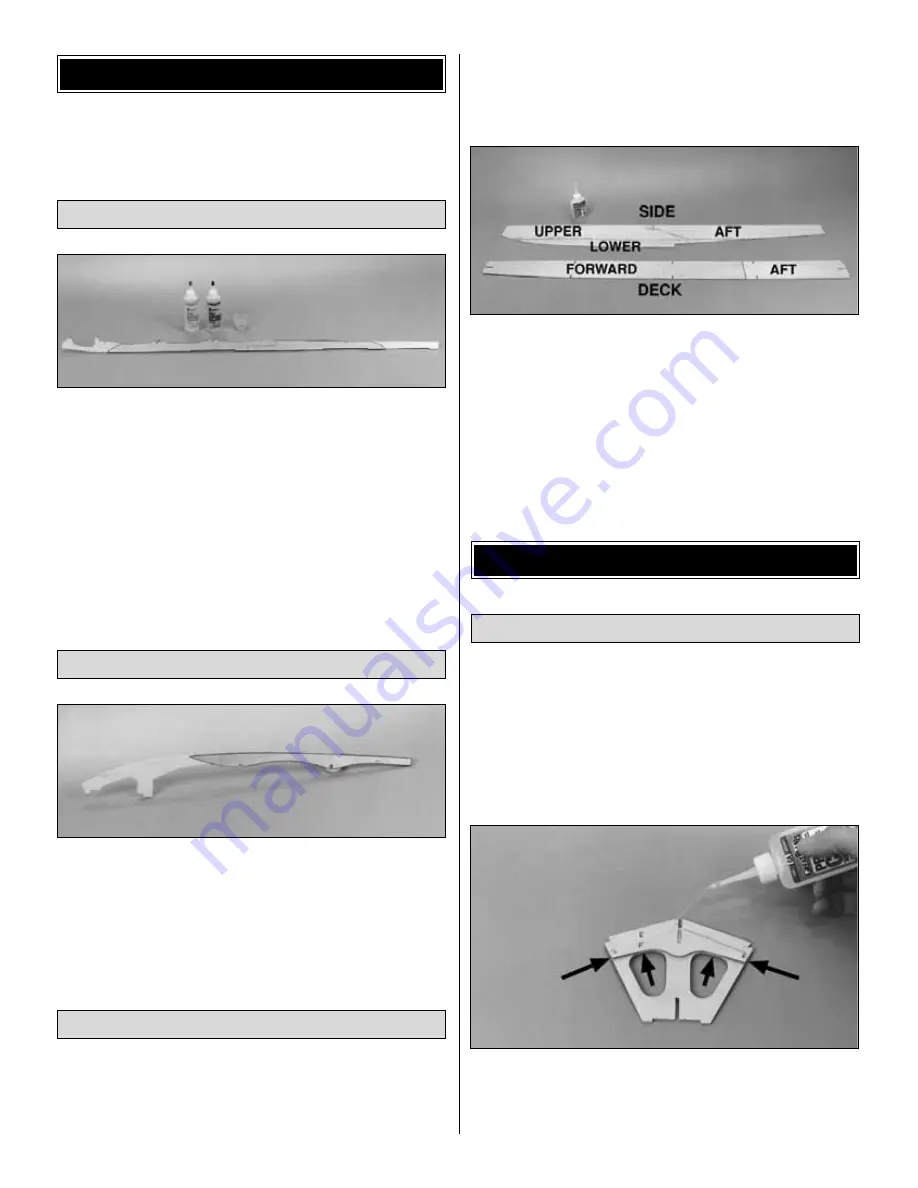

1. Trial fit the die-cut 3/32" balsa upper float side,

lower float side and aft float side. Make adjustments if

necessary. When satisfied with the fit, use thin CA to glue

the three pieces together over a building table covered with

waxed paper. After the CA has cured, use 150-grit

sandpaper and a sanding block to sand both sides of the

float side flat and smooth. Make another float side,

identical to the first.

❏

2. Use thin CA to glue the die-cut balsa forward deck to

the aft deck. After the CA has cured, sand both sides of

the deck flat and smooth.

NOTE: If your float parts do not match each photo exactly,

it is because these instructions are written for all three

sizes. Regardless of which size Spor t Float you are

building, the forward end of the float deck is the end

that tapers slightly.

❏

1. Drill 1/8" holes through the punch marks in the die-cut

1/8" plywood forward and aft strut mounting plates.

❏

2. With the die-cut 1/8" plywood former doubler F

centered on the die-cut 1/8" plywood former E, align the

bottom edge of the doubler F with the lightening holes in

former E. Glue the pieces together with thin CA.

Framing

CONSTRUCTION OF 20, 40 & 60

Sides and Deck

Forward Keel

Spine

60 FLOATS PREASSEMBLY

6

Содержание Sport Floats

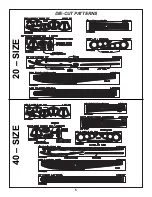

Страница 4: ...4 DIE CUT PATTERNS 60 SIZE...

Страница 5: ...5 DIE CUT PATTERNS 20 SIZE 40 SIZE...

Страница 21: ......