Note: Before reinstalling the cable into the guide, apply a

light coat of oil or petroleum jelly to the cable to prevent

future corrosion.

B. Remove the threaded coupler from the nylon clevis, slide

the cable back into the outer pushrod tube, then solder the

cable to the coupler. Thread the clevis back onto the

coupler. Then attach it to the rudder horn. Make final

adjustments by screwing or unscrewing the nylon clevis at

either end of the cable.

60 Floats Only

After performing steps A and B, continue with step 8.

A. Screw a nylon clevis to the .074" x 12" threaded rod.

Then temporarily fasten the clevis to the rudder horn.

Holding the water rudder on the float and the rudder on the

airplane in a neutral position, determine where the threaded

rod and the cable will be joined with the coupling sleeve.

Then cut the rod to length. Remove the cable from the guide

tube, and then cut the cable to length. Hint: A Great Planes

cut-off wheel (GPMR8200) works well for cutting cable like

this without fraying the end. Cut the guide tube to a length

that will not interfere with the split coupler when it is

soldered onto the cable and the cable moves in and out.

Note: Before reinstalling the cable into the guide, apply a

light coat of oil or petroleum jelly to the cable to prevent

future corrosion.

B. Slide the cable back into the guide tube. Then join the

threaded rod to the cable by soldering the coupling sleeve

to both pieces. Make final adjustments by screwing or

unscrewing the nylon clevis at either end of the cable.

❏

8. Mount another 1/8" plywood mount plate and the

other cut hump strap near the rear of the guide tube.

❏

9. Test the actuation of the water rudder on the floats.

The water rudder and the rudder on the model must both

be neutral and move in the same direction.

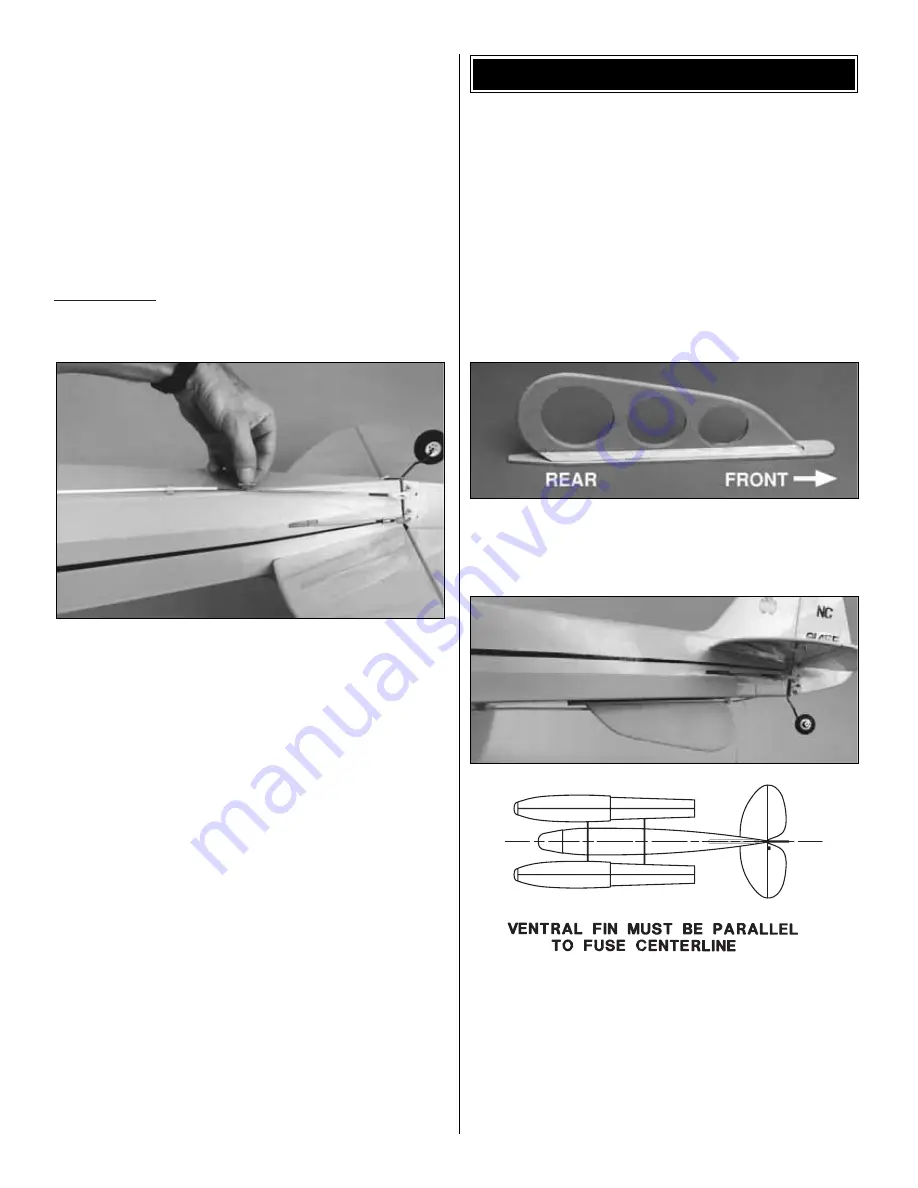

The purpose of the ventral fin is to increase yaw stability.

Some models may be flown successfully without the ventral

fin, but we strongly recommend that you add the ventral fin

to your airplane when flying with Great Planes Sport Floats.

❏

1. Laminate the die-cut 3/32" balsa ventral fins with

6-minute epoxy. Note: The 60 ventral fin is two pieces of

die-cut 1/8" plywood. Hint: Clamp the ventral fins together

while the epoxy cures by laying weights on top of them over

a flat work surface covered with wax paper. After the glue

has cured, use a sanding block and 150-grit sandpaper to

sand the ventral fin flat, remove any excess glue, and round

the edges. Final sand with 320 to 400-grit sandpaper.

❏

2. Making sure the ventral fin is perpendicular to the

die-cut 1/8" plywood ventral fin base, glue the pieces

together with medium CA. Then glue the 1/4" balsa triangle

stock to the fin and base.

❏

3. Cover the assembled ventral fin to match your model.

Then mount it to the bottom of the fuselage right on the

centerline of the fuselage. The suggested mounting method

is double-sided foam mounting tape. An alternate mounting

method would be to use #2 x 3/8" sheet metal screws. If you

use screws, 1/8" plywood blocks should be glued to the

inside of the bottom sheeting where the screws are located.

❏

4. Balance your airplane again, after adding the ventral fin.

VENTRAL FIN

19

Содержание Sport Floats

Страница 4: ...4 DIE CUT PATTERNS 60 SIZE...

Страница 5: ...5 DIE CUT PATTERNS 20 SIZE 40 SIZE...

Страница 21: ......