❏

8. Cut a small notch in the servo hatch for the servo

extension wire. Install a 12" servo extension wire on the

servo lead. Secure the connection with tape, keeping the

connection as water tight as possible. Position the servo

hatch onto the rails with the taped connection inside the

float. Secure the hatch into place with some clear

waterproof tape. Put a dab of silicone glue where the servo

wire exits the hatch to waterproof it.

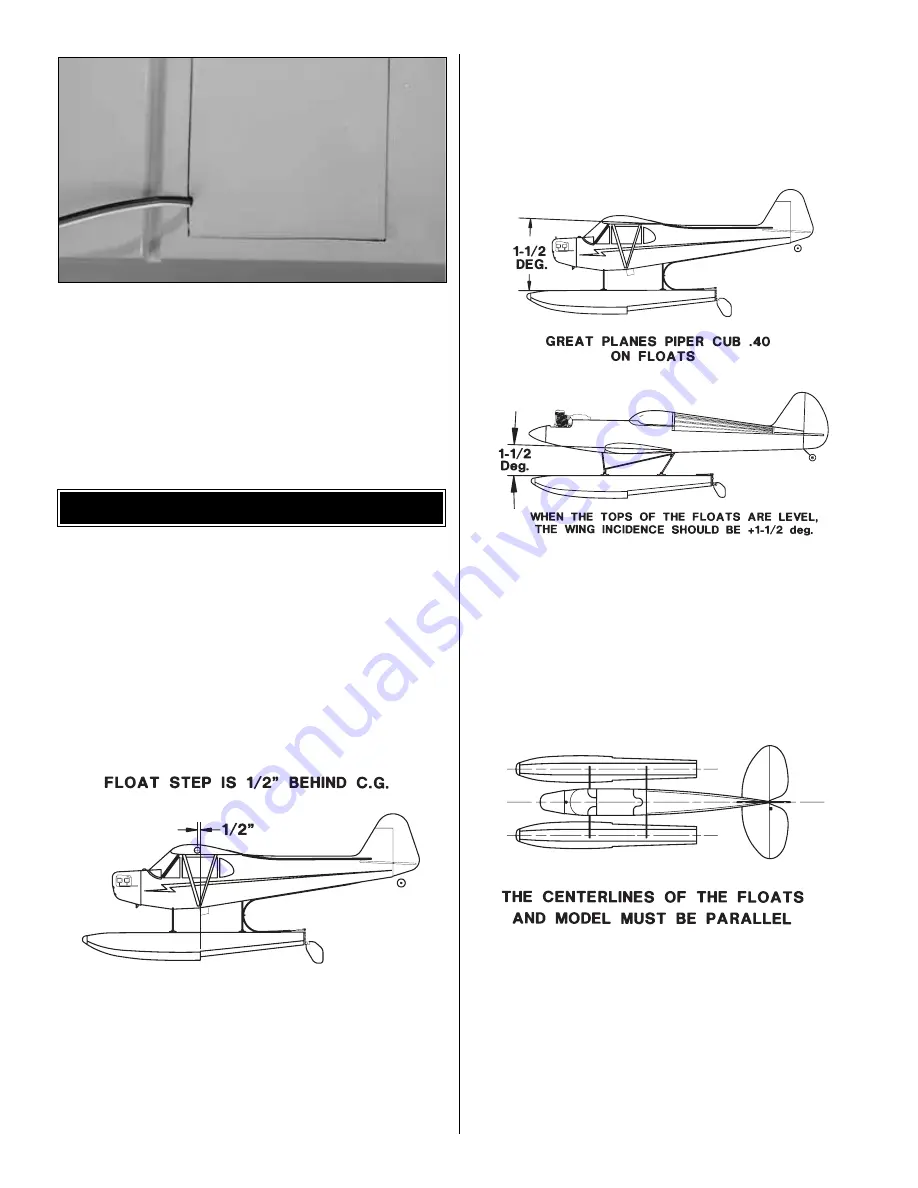

Before you continue, take a break from building and

study the following information to be sure you

understand the positioning of the floats in relation to

the wing and fuselage.

While the following instructions show the Sport Floats on

Great Planes Piper Cubs, there are general tips and

guidelines that apply to all models which will insure proper

handling characteristics in the water and good landing and

takeoff tendencies.

The relationship between the “step” on the floats and the

center of gravity on the model is important. First, the floats

should be mounted on the model so the step is positioned as

detailed in the “Step Sketch” for your particular model. Then,

when the floats are mounted on the model, move the C.G.

slightly forward as listed below. Although you may have added

the recommended ballast inside the front of the float, in some

cases a little more ballast may be required on the model.

• For 60-size floats: Move the CG (Balance point) 1/2"

ahead of the manufacturers recommended CG.

• For 40-size floats: Move the CG (Balance point) 3/8"

ahead of the manufacturers recommended CG.

• For 20-size floats: Move the CG (Balance point) 9/32"

ahead of the manufacturers recommended CG.

Another important relationship between the wing and the

floats is the relative “angle of attack.’’ With a virtually flat

bottom wing such as a Piper Cub, the deck of the floats

should be parallel to the bottom of the wing. Since the Cub

does not have a truly flat wing, this yields a slight positive

wing incidence in relation to the floats, and the airplane will

tend to rise off the water at the correct time. If you have a

model with a symmetrical wing, the wing incidence in

relation to the float deck should be positive 1-1/2 degrees.

Finally, each float should be set so that it is parallel to the

centerline of the fuselage.

POSITIONING OF FLOATS

9