❏

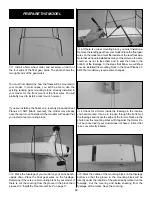

2. Mount the water rudder assembly in the location shown in

the above photo. The top of the mounting bracket should be

3/4" [19mm] from the top of the float, on the centerline of the

transom (rear of the float). Mark the location of the holes in the

mounting bracket on the transom. Drill a 5/64" [2mm] hole at

the marked locations and mount the water rudder assembly to

the transom with two #4 x 1/2" [12.7mm] sheet metal screws

and two #4 flat washers.

❏

3. Drill a 25/64" [9.9mm] hole in the transom of the float

as shown. This hole must be drilled very carefully as there

is a wood block installed in the transom for mounting the

water rudder assembly. If the hole is drilled too close to the

water rudder assembly, the drill bit will catch on the edge of

the wood block, causing the drill bit to twist sideways. Hold

the float up to a strong light so that you can determine

where the edge of this block is located. Drill the hole as

close to the water rudder assembly as possible, while still

missing the wood block. If you can't locate the edge of the

wood block, drill a locating hole as noted in the photo. If the

locating hole hits wood, drill another hole farther over.

Note: If you don’t have a 25/64" [9.9mm] drill use a 3/8" [9.5mm]

drill, and then slightly enlarge the hole with a hobby knife.

❏

4. Cut the .074 x 17-1/2 [445mm] wire pushrod to a

length of 12" [25.4mm]. Cut the threaded portion of the wire

off, leaving a 12" [25.4mm] wire with no threads. Make a

small bend 3/4" [19mm] from the end of the wire. Insert the

wire into the rubber bushing.

❏

5. Insert the wire and rubber bushing into the hole you

drilled in the transom. The rubber bushing is easier to insert

if you stretch it on the wire as it is inserted. Use a

screwdriver to carefully poke it through as needed. The

rubber bushing is now inside the float. Secure the rubber

bushing to the transom with some silicone rubber glue or

medium CA. Insert the wire into the screw-lock connector.

❏

6. Mark the location of the hole in the servo arm on the

servo mounting rail and on the wire pushrod. Make sure that

the water rudder is centered and the pushrod is centered in

the screw-lock connector.

❏

7. Make a 90-degree bend in the wire at the mark. The

bend should face the right side of the float as shown in the

photo. Enlarge the middle hole of the servo arm with a 5/64"

[2mm] drill. Insert the pushrod into the servo arm and

secure it with a Faslink connector. Remove the screw and

servo arm from the servo. Plug the servo into the receiver

and center the trims on the transmitter. Turn the radio on,

and then push the servo arm onto the servo with the arm at

90 degrees to the servo. Install the mounting screw into the

servo arm. Turn the radio off and unplug the servo.

8