❏

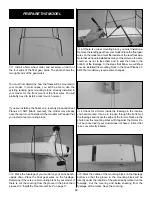

4. Assemble the Nylon rudder bearing, rudder post,

aluminum bracket and nylon control horn as shown in

the photo. Hold the control horn in place with a #2 x 3/16"

[4.8mm] screw.

❏

5. Assemble the water rudder to the aluminum bracket with a

4-40 x 1/4" [6.4mm] socket head cap screw and 4-40 lock

nut. Tighten the nut, but leave it loose enough that the water

rudder can pivot freely in the bracket. If the bracket does not

have a hole drilled in it, use a 1/8" drill to drill the hole.

❏

6. Drill a 5/64" [2mm] hole in the aluminum bracket and

rudder post at the location shown in the above photo,

making sure the water rudder and control horn are aligned

as shown. Install a 2-56 x 3/8" [9.5mm] screw and 2-56 nut

to hold the bracket to the rudder post. Use Great Planes Pro

Threadlocker

™

to hold the nut in place.

Hint: Center punch the bracket before drilling the hole.

❏

7. Install a screw-lock connector, nylon retainer and

4-40 x 1/8 [3.2mm] socket head cap screw in the outer

hole of the long tiller arm on the water rudder. Also install

the rubber band.

If you are installing a servo inside the right float, proceed to

step 2.

❏

1. Do this step only if you are installing a pushrod from the

aircraft rudder to the water rudder. Mount the water rudder

assembly in the location shown in the above photo. The top of

the mounting bracket should be even with the top of the float,

on the centerline of the transom (rear of the float). Mark the

location of the holes in the mounting bracket on the transom.

Drill a 5/64" [2mm] hole at the marked locations and mount the

water rudder assembly to the transom with two #4 x 1/2"

[12.7mm] sheet metal screws and two #4 flat washers.

Proceed to “Prepare the Model” on Page 10.

Install the Water Rudder

7