❏

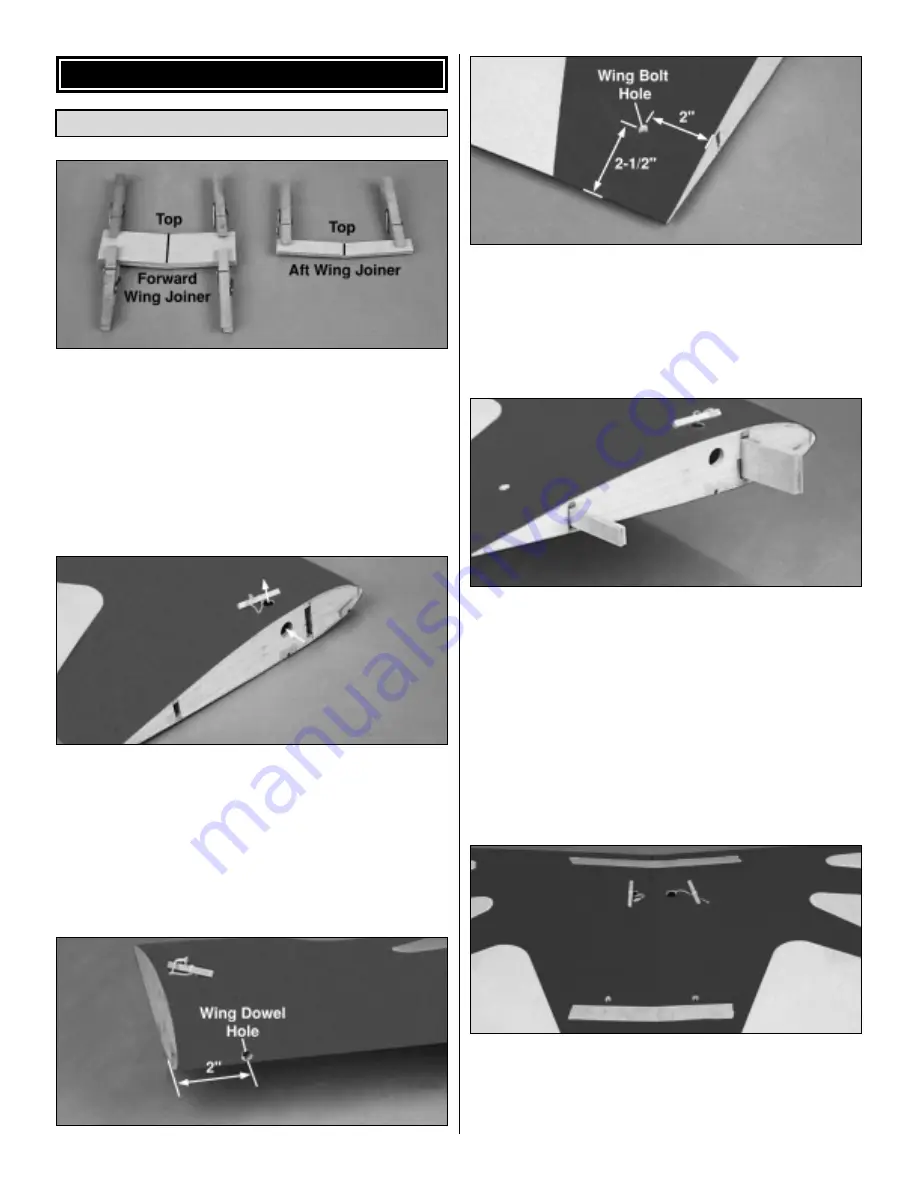

1. Use 5-minute epoxy to glue the three plywood

forward

wing joiners

together and the two

aft wing joiners

together. Use clothespins or c-clamps to clamp the joiners

together until the epoxy cures. Wipe off any excess epoxy

with a paper towel and isopropyl alcohol before it cures.

Draw a vertical

centerline

on the forward and aft wing joiners.

❏

2. Use a sharp hobby knife to cut the covering from the

servo cord exits

on the top of each wing half. Carefully

untie the string from the stick at the root rib and route the

string through the servo cord exit. Re-tie the strings around

the stick.

❏

3. Use a sharp hobby knife to cut the covering from the

wing dowel holes

in the leading edge and the

wing bolt

holes

at the trailing edge of each wing half. The wing dowel

holes are approximately

2" [50.8mm]

from the wing root.

The wing bolt holes are approximately

2" [50.8mm]

from

the wing root and

2-1/2" [63.5mm]

from the trailing edge.

❏

4. Test fit the wing joiners in both wing halves. A snug fit

is desirable. If the joiners do not fit properly, lightly sand the

edges and sides of the joiners.

Note:

The plywood wing

joiners have a slight dihedral angle. This angle should point

toward the top of the wing. When satisfied with the fit of the

wing joiners, use

30-minute epoxy

to glue the joiners in the

left wing half. Use plenty of epoxy, making sure the joiners

are glued to the spars and shear webs. Before the epoxy

cures, make sure the joiners are straight and in good

contact with the spars. Wipe off any excess epoxy from the

root rib and the wing covering using a paper towel

dampened with isopropyl alcohol.

❏

5. Test fit the two wing halves together. The wing halves

should seat together without any gaps and the front and

back edges of each wing should line up with each other.

Completely cover the exposed portion of the wing joiners,

spars and root ribs with 30-minute epoxy. Slide the two

Join the Two Wing Halves

WING ASSEMBLY

6