a nylon

Faslink.

Cut the excess pushrod so it slightly

protrudes out of the Faslink.

Note:

If necessary, enlarge the hole in the servo arm with a

5/64" [2mm] drill bit (or a #48 bit for precision).

❏

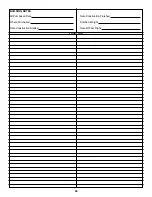

18. In the second wooden dowel, drill 5/64" [2mm] holes

through the dowel, 2" [50.8mm] from each end. On one of

the ends, also drill a hole 1-1/2" [38mm] from the end. On

each end of the dowel, use a hobby knife to cut a groove

from the holes to the end of the dowel, deep enough for a

2-56 threaded pushrod to fit in. The groove for the 1-1/2"

[38mm] hole should be on the opposite side from the

groove for the 2" [50.8mm] hole.

❏

19. Cut 1-1/2" [38mm] off of the non-threaded end of a

2-56 x 12" threaded pushrod. From the threaded end of a

2-56 x 36" pushrod, cut an 11" [279.4mm] long piece. Cut a

second non-threaded 11" [279.4mm] piece from the same

36" pushrod. Make a 90° bend 1/4" [6.4mm] from the non-

threaded end of the 10-1/2" and both 11" pushrods. Insert

the two 11" [279.4mm] pushrods in the holes, 2" [50.8mm]

from the end of the wooden dowel. The 10-1/2" [266.7mm]

pushrod is inserted in the hole 1-1/2" [38mm] from the end.

❏

20. Slide a 2" [50.8mm] piece of shrink tubing over each

end of the wood dowel and pushrods. Use a heat gun to

shrink the tubing tight around the dowel and use thin CA to

secure it to the dowel. This is now the elevator pushrod.

❏

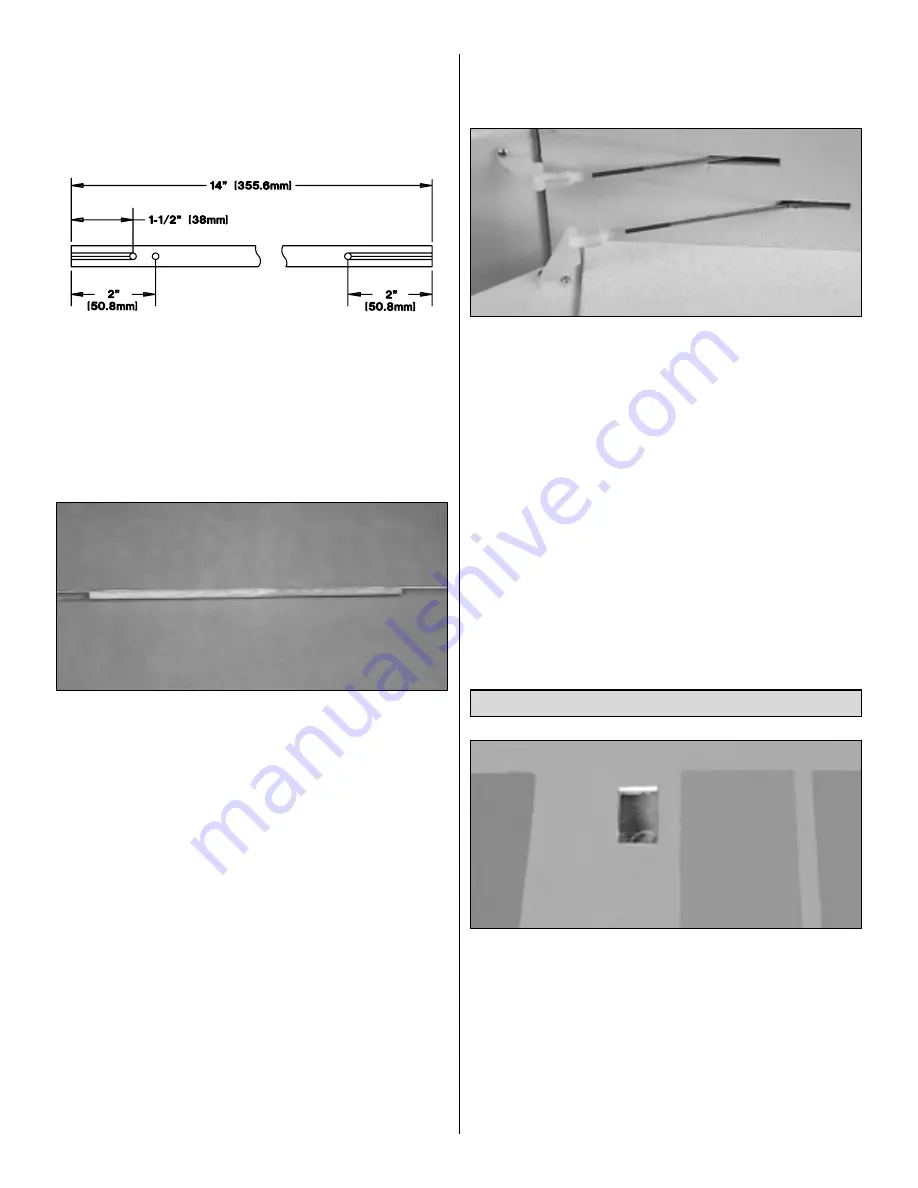

21. Following the same procedure used to install the

rudder pushrod, insert the elevator pushrod into the

fuselage with the two threaded rods exiting out the elevator

exit slots.

Hint:

Bend the pushrods apart slightly. It’s best to

guide one pushrod out one of the pushrod exits. Align the

second rod with the other pushrod exit and use a hobby

knife or small flat screwdriver to guide it out the exit. Slide

silicone clevis retainers over the threaded rods and screw

nylon clevises 14 turns onto the threaded rods.

❏

22. Attach a control horn to both clevises. Align the

adjustment holes in the control horns with the hinge line of

the elevator. Mark the control horn’s mounting holes.

❏

23. Drill a 3/32" [2.4mm] hole at each mark. Mount the

elevator control horns to the elevators with the backing

plate and 2-56 x 5/8" machine screws. Slide the silicone

retainer over the clevis to secure it in place.

❏

24. With the elevator servo centered and the elevators in

the neutral position, use a felt-tip pen to mark where the

pushrod crosses the mounting holes in the servo arm.

❏

25. Make a 90° bend at the mark you made. Insert the

elevator pushrod in the elevator servo horn and secure it

with a nylon Faslink. Cut the excess pushrod so it slightly

protrudes out of the Faslink.

Note:

If necessary, enlarge the

hole in the servo arm with a 5/64" [2mm] drill bit (or a #48

drill for precision).

❏ ❏

1. Trim the covering from the aileron servo tray on the

bottom of the right wing half.

❏ ❏

2. Plug a 24" [609.6mm] servo extension into the

aileron servo. As a precaution, use tape or shrink tubing

(not included) to prevent the connectors from separating.

❏ ❏

3. Carefully pull the string in the aileron servo bay out

enough to tie it to the end of the 24" servo extension.

Gently

pull the extension through the wing until it exits at

the center of the wing.

Install the Aileron Servos

14