16 307-706

SERVICE

Gun Disassembly

WARNING

Installing and servicing this equipment requires

access to parts which may cause electrostatic

shock or other serious bodily injury if the work is not

performed properly. Do not install or service this

equipment unless you are trained and qualified.

Follow the Pressure Relief Procedure Warning,

page 11, before servicing the gun or any part of the

system. Disconnect the fluid hose from the gun.

NOTE: Check all possible remedies in the

Troubleshooting Charts before disassembling

the gun.

CAUTION

If the plastic parts of the gun must be held

securely, ALWAYS clamp them in padded vice

jaws to prevent damage to the parts.

ALWAYS lubricate o–rings and seals with petro-

leum jelly.

ALWAYS remove gun from worksite for service or

repair. Service or repair area must be clean.

Flush the gun as described under Flush the Spray Gun.

Follow the Pressure Relief Procedure Warning on

page 11. Disconnect the air and fluid line from the gun.

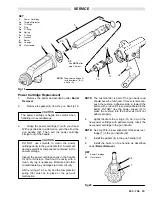

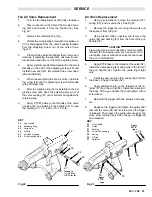

Fig 11

KEY

11

Retaining Nut

12

Air Cap

13

Spray Tip

GG

Electrode Wire

GG

11

12

13

Electrode Wire Replacement

1.

Unscrew the retaining nut (11). Remove the air

cap (12) and spray tip (13). See Fig 11.

2.

Use a needle nose pliers to gently pull the elec-

trode wire (GG) out the back of the spray tip.

3.

Install the long end of the new wire in the hole

closest to the tab of the tip. See Fig 11. Push the wire

in, aligning the short end of the wire with the other

hole in the tip. Pull on the front of the wire to seat it.

NOTE: A box of ten electrodes is included in the tool

kit (63).

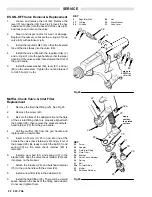

Ball Seat Housing & Resistor Replacement

1.

Unscrew the retaining nut (11) . Remove the air

cap (12) and spray tip (13). See Fig 11.

2.

Insert the special wrench (63d) in the front of the

gun. While triggering the gun, unscrew the ball seat

housing (14) and remove it. See Fig 12.

3.

If you are replacing the fluid needle assembly, do

not reassemble the gun.

If no further service is required, install the new hous-

ing in the reverse order of disassembly. Torque the

ball seat housing to 1.1 N

m (10 in-lb)

(snug); DO

NOT OVER TIGHTEN.

CAUTION

DO NOT over tighten the ball seat housing (14).

Excess torque will damage the housing.

Fig 12

KEY

14

Ball Seat Housing

63d

Wrench

63d

14

Torque to

1.1 N

m

(10 in-lb)

63d

14

Содержание PRO AA4000

Страница 2: ... ...