STEP 5 - TETHER TRACK® INSTALLATION

5.1

Refer to the enclosed General Arrangement Drawing to plan the sequence in which the monorail sections will

be installed. Monorail sections that have splice plate style connections (Z and ZD styles) may need to be

assembled to the mating monorail section prior to lifting and installing on the headers. Do not lift greater than

two assembled (splice plate style connection only) monorail sections at a time. Do not lift assemblies greater

than 54 feet long. Do not allow more than 13 feet of track to extend past the header without support. For

sleeve and truss plate style connections (S, SL, SLX and SLD styles), only lift these sections individually (not

assembled).

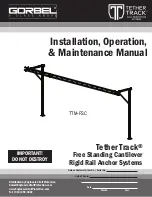

Splice Joint Plate Style Connections

5.2

Align mating monorail sections and install hardware (

diagram 5A

).

Verify track flanges (trolley wheel running surfaces) are aligned

before tightening. Run a finger on the inside of the track flange and

use a soft blow mallet to align plates until no lip is

felt. Also check alignment of mating sections for bow

and camber. Steel shims (by others) may be used

between the splice plates to adjust any

misalignment. Tighten hardware to 50 ft.-lbs. of

torque per nut.

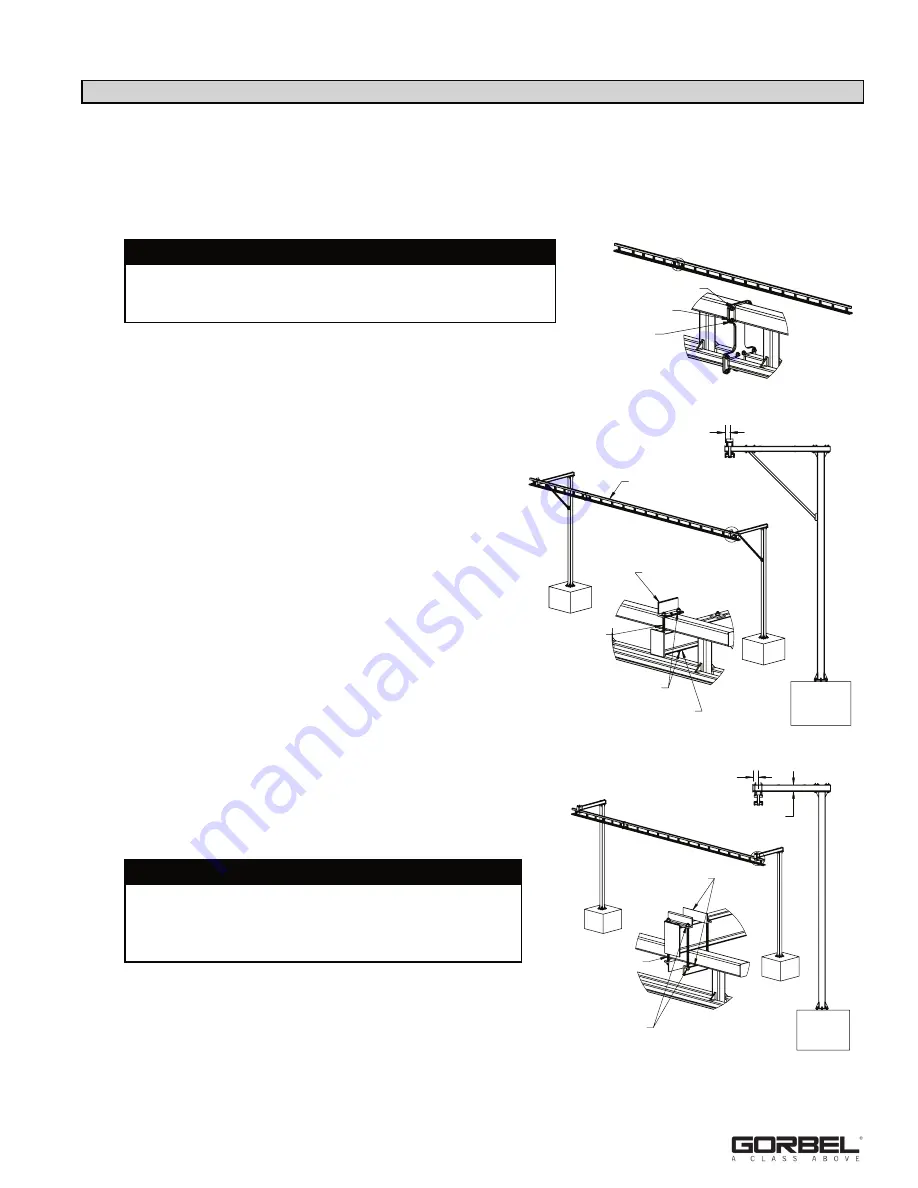

Monorail to Header Connections

5.3

The first monorail section(s) to install shall be

connected to two headers. Subsequent sections will

be splice connected to the previously installed

section and a header.

Diagram 5B

shows the top

tube on top of the header.

Diagram 5C

shows the

top tube below the header. Refer to the enclosed

General Arrangement Drawing to determine the

correct orientation. Threading the header through

the monorail truss (

diagram 5B

) is the most

common. When there is at least a 1-1/2” clearance

between the header’s oversized end plate and the

space between the track and top tube on the truss,

the threaded orientation is used. The monorail centerline

should be located from the end of the header as

shown in

diagram 5B

, for threaded mounting or as

shown in

diagram 5C

, for under hung mounting.

5.4

Using proper rigging practices (by others) lift the monorail

section(s) into place and secure to the header using spine

clamp angles, clamp plates, and hardware provided

(

diagrams 5B

and

5C

).

Note:

For outdoor systems, all hardware may not be

galvanized. You will need to use cold galvanizing spray

provided on any unplated/galvanized hardware (refer to

steps 1.5

and

1.6

, page 4).

TOP TUBE

4 1/2" FOR TOP TUBE WIDTH <= 3"

5 1/2" FOR TOP TUBE WIDTH <= 5"

6 3/4" FOR TOP TUBE WIDTH > 5"

SPINE CLAMP ANGLE

SQUARE CLAMP PLATE

5/8"-11 THREADED ROD

FLAT WASHER & LOCK NUT (OUTDOOR)

LOCK WASHER & HEX NUT (INDOOR)

Diagram 5B.

Installing threaded monorail.

9

9/18 Rev B

6 3/4" FOR 8" HEADER DEPTH

5 1/2" FOR SMALLER HEADERS

HEADER DEPTH

SPINE CLAMP ANGLES

FLAT WASHER &

LOCK NUT (OUTDOOR)

LOCK WASHER &

HEX NUT (INDOOR)

5/8"-11 THREADED ROD

Diagram 5C.

Installing under hung monorail.

1/2"-13 X 1-1/2" HHCS

FLAT WASHER

LOCK NUT

Diagram 5A.

Plate style splice joint detail.

WARNING

The locations of the runways cannot deviate from the locations

shown on the drawing. Changing the locations will void the

design and the warranty.

WARNING

The largest monorail assembly required to install may be

54 feet long and weigh 1300 lbs. Do not perform

installations under adverse weather conditions or without

the proper lifting equipment.